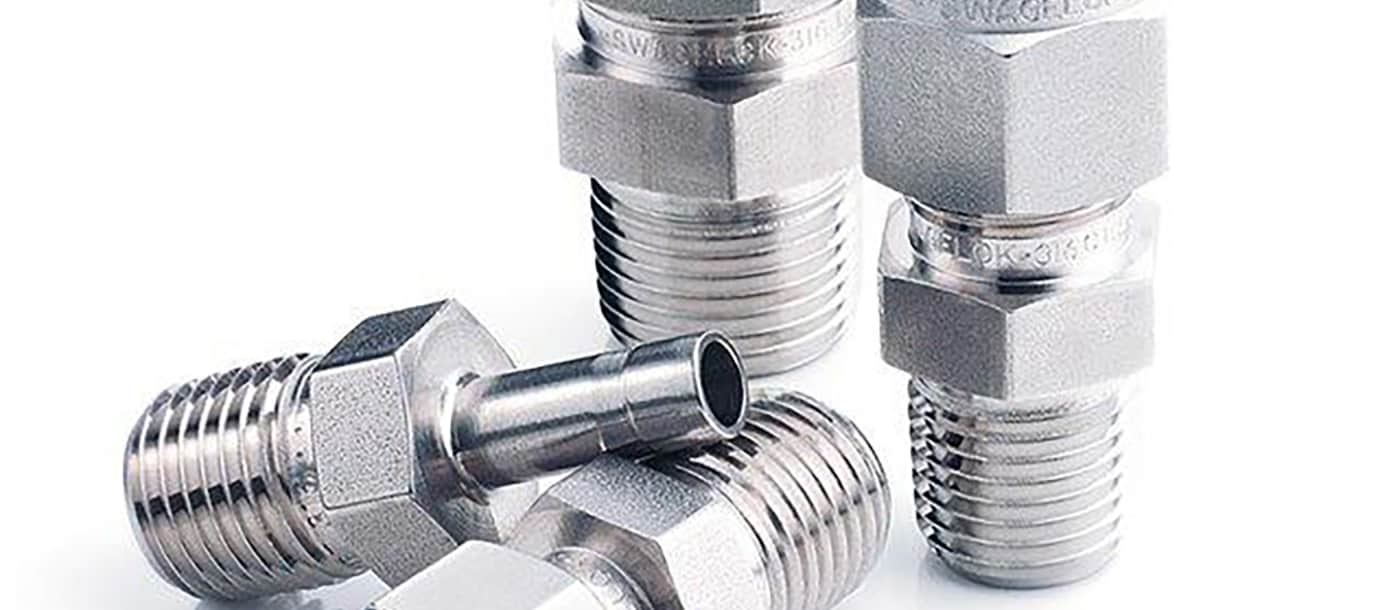

High Purity PFA Fine Thread Flare Fittings

Swagelok® PFA fine thread flare fittings provide safe, efficient fluid system operation in high-purity applications. They are ideal for the use in semiconductor production and aggressive chemical environments.

Get Help Selecting PFA Flare FittingsSwagelok® PFA fine thread flare fittings are made from molded fluoropolymer. These fittings provide tensile strength, resistance to permeation, thermal stability, and maintain leak-tight connections in demanding fluid systems. Swagelok PFA fittings are compatible with other ultrahigh-purity products, including valves and tubing, to create a fully integrated system suitable for handling aggressive fluids. The fittings are available in a range of shapes and sizes, such as straight, elbow, and tee configurations. Depending on application needs, they are offered with standard PFA bodies and PVDF nuts, or all-PFA and all-PVDF configurations.

Specifications

| Pressure Ratings | Up to 275 psig (18.9 bar) |

| Temperature Ratings | 75 to 350°F (23 to 176°C) |

| Body | High-purity PFA |

| Nuts | PVDF (standard), PFA (optional) |

| End Connection | Sizes: 1/8 to 1 in. Configurations: Straights, elbows, tees, caps, plugs, nuts, PVDF fittings |

High Purity PFA Fine Thread Flare Fitting Catalogs

Locate detailed product information, including materials of construction, pressure and temperature ratings, options, and accessories.

Features: Available in 1/4, 3/8, 1/2, 3/4 and 1 in. tube sizes; PFA and PVDF nut options; A wide variety of configurations

An Introduction to Fittings: Identifying Thread Size and Pitch

Even the most seasoned professionals can experience difficulty identifying threads. Swagelok product manager Andy Hitchcock explains how to identify thread size and pitch on your fittings using a caliper, pitch gauge and thread identification guide.

Read About Fitting SelectionSwagelok Resources Curated for You

Reliable Fluid System Solutions for the Scientific Frontier

Learn why Finnish dilution refrigerator manufacturer Bluefors trusts Swagelok for fluid system components and solutions that help enable quantum computing, experimental physics, and more.

Building More Profitable Semiconductor Fabs

Learn why choosing high-quality fluid system parts and assemblies can contribute to faster semiconductor fabrication facility construction, and lower total cost of ownership over the facility’s lifetime.

Improve Semiconductor Yield with Optimized Alloys

Discover how semiconductor fabricators can improve end-to-end production yields and improve long-term profitability by selecting the right metals for critical fluid system components.

Q&A: Semiconductor Manufacturing Past, Present, and Future

Find out how collaboration between semiconductor tool OEMs, microchip manufacturers, and fluid system solutions providers has enabled the semiconductor market to keep up with the demands of Moore’s Law for decades, and where we go from here.