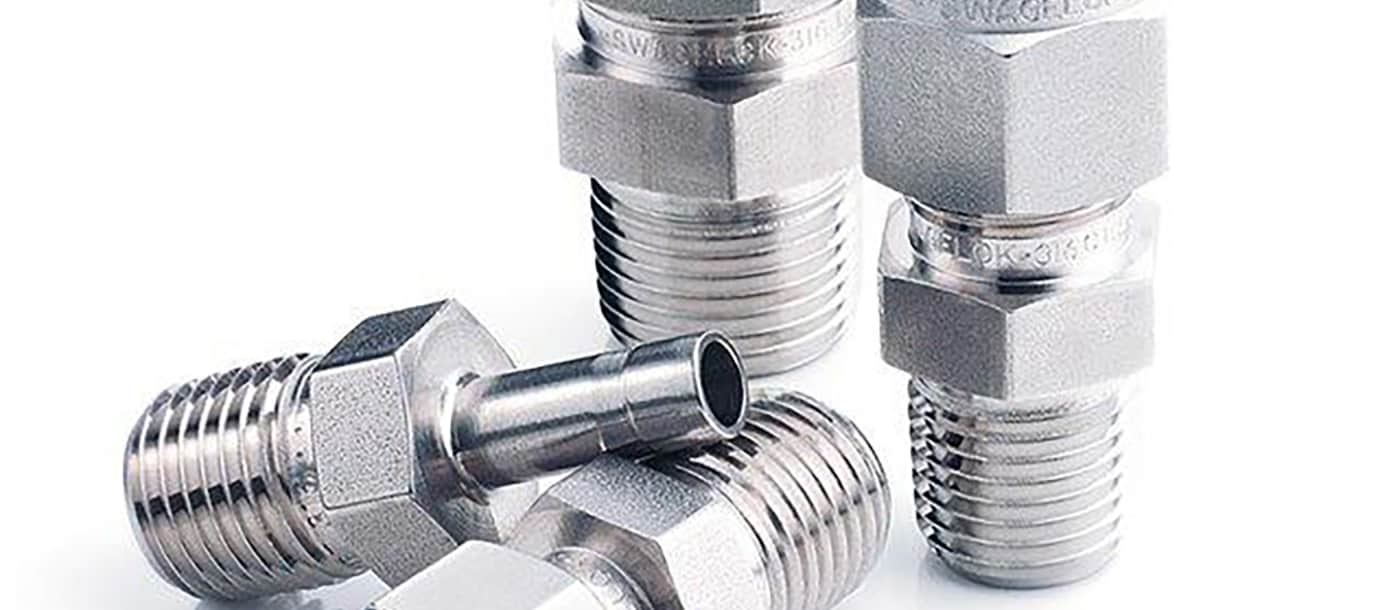

世伟洛克® PFA 细螺纹扩口接头由模压含氟聚合物制成。这些接头具有抗拉强度、抗渗透性和热稳定性的特点,并能在要求严格的流体系统中保持无泄漏连接。世伟洛克 PFA 接头可与包括阀门和卡套管在内的其他超高纯产品兼容,从而形成一套适合处理腐蚀性流体的全集成系统。这些接头有多种形状和尺寸可供选择,例如直通、弯头和三通配置。根据应用需求,它们可采用标准 PFA 本体和 PVDF 螺母,或全 PFA 和全 PVDF 配置。

规格

| 压力额定值 | 最高 275 psig (18.9 bar) |

| 温度额定值 | 75 至 350°F(23 至 176°C) |

| 本体 | 高纯 PFA |

| 螺母 | PVDF(标准)、PFA(可选) |

| 端接 | 尺寸:1/8 to 1 in. 配置:直通、弯头、三通、管帽、堵塞、螺母、PVDF 接头 |

高纯 PFA 细螺纹扩口接头目录

查找详细的产品信息,包括结构材料、额定压力和温度、选购件及配件。

High Purity PFA Fine Thread Flaring Fittings

Features: Available in 1/4, 3/8, 1/2, 3/4 and 1 in. tube sizes; PFA and PVDF nut options; A wide variety of configurations

接头简介:识别螺纹尺寸和螺距

即使是有经验的专业人员也会遇到识别螺纹的困难。世伟洛克产品经理 Andy Hitchcock 解释如何使用游标卡尺、螺纹规和螺纹识别指南识别接头上的螺纹尺寸和螺距。

了解有关接头选型的信息世伟洛克为您精心准备的产品、服务和解决方案

适合于科学前沿的可靠流体系统解决方案

了解为何芬兰稀释制冷机制造商 Bluefors 信赖世伟洛克提供的流体系统部件和解决方案,来助力于量子计算、实验物理学等领域。

建造更具盈利能力的半导体工厂

了解为何选择高质量的流体系统零件和组件有助于加快半导体制造工厂的建设,并在工厂的整个使用寿命内降低总体拥有成本。

利用优化的合金提高半导体制造良率

了解半导体制造商如何通过为关键流体系统组件选择合适的金属材料,提高端到端制造良率并提高长期盈利能力。

问答:半导体制造的过去、现在与未来

了解半导体OEM设备商、微芯片制造商与流体系统解决方案提供商之间的协作如何使半导体市场在数十年来能够满足摩尔定律的要求以及未来的发展方向。