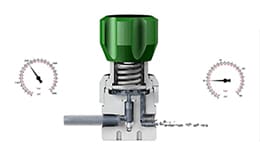

世伟洛克罐封调压阀对于确保在含有危险流体的储罐周围地操作人员和旁观者的安全至关重要。它们能在蒸汽空间中保持一致的惰性气体压力水平,防止危险蒸汽泄漏。

罐封调压阀可降低与压力密封罐相关的安全风险。

- TBRS 系列调压阀允许气体进入罐体以保持恒压,防止抽气时罐体坍塌

- TBVS 系列背压调压阀将余压排放到蒸汽回收系统,防止意外排放

这些调压阀可在罐封应用中提供精确的压力控制。其特点包括:设定压力弹簧上的细螺距螺纹可提高可调节性;高灵敏度的隔膜感应机构可实现精确的压力检测;外部反馈回路可提高调压阀的性能。此外,这些调压阀还采用 316L 不锈钢制造反馈管、调压阀本体和提升阀芯套筒等组件,能够经受恶劣环境的考验,确保耐腐蚀性和长期耐用性。

规格

| 材料 | 316L 不锈钢结构 |

| 端接尺寸 | 1/2、1 和 2 in. |

| 工作压力 | 最高 232 psig (16.0 bar) |

| 压力控制范围 | 0.07 至 0.14 psig(2.0 至 4.0 in. H2O,5 至 10 mbar)到 0.72 至 11.6 psig(20 至 321 in. H2O,50 至 800 mbar) |

| 流量系数 (Cv) | 0.20、0.30、1.00 |

| 温度 | –4 至 212°F(–20 至 100°C) |

罐封调压阀样本

查找有关我们的罐封调压阀的全面详细信息,包括结构材料、配件、压力和额定温度。

Tank Blanketing Pressure Regulators, RHPS Series

Swagelok offers pressure-reducing and vapor recovery (back-pressure) tank blanketing regulators for systems requiring an inert gas in the vapor space of a storage tank.

世伟洛克调压阀资源

管理调压阀的供压效应 (SPE)

供压效应也称依赖性,是指调压阀中的进口压力变化与出口压力变化之间互为反比关系。了解如何根据世伟洛克的建议管理调压阀中的这种现象。

全面的测试如何确保可靠的调压阀性能

您是否想知道设计用于在极端条件下运行的产品需要接受哪些测试?跟随用于零度以下环境的RHPS系列工业调压阀的开发之旅,让我们来看看实验室的情况。

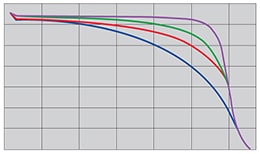

如何使调压阀流量曲线更平直以减少压力衰减

压力衰减是每个减压阀均难以避免的问题。了解如何利用各种圆顶加载调压阀配置,尽可能地减少压力衰减并使调压阀流量曲线更平直。

如何使用调压阀来降低分析仪器系统中的延时

在分析系统中,延时常常被低估或误解。降低这种延时的一种方法是使用压力控制调压阀。了解如何通过这些技巧来管理分析系统的延时。