Swagelok®-Druckminderer, dombelastet

Die dombelasteten Druckminderer für den allgemeinen industriellen Einsatz (Serie SGRD) sowie für Anwendungen mit hoher Empfindlichkeit (Serie SHRD) eignen sich für ein breites Spektrum an Einsatzbereichen, in denen eine manuelle oder ferngesteuerte Bedienung des Reglers und eine genaue Regelung des Einstelldrucks erforderlich ist.

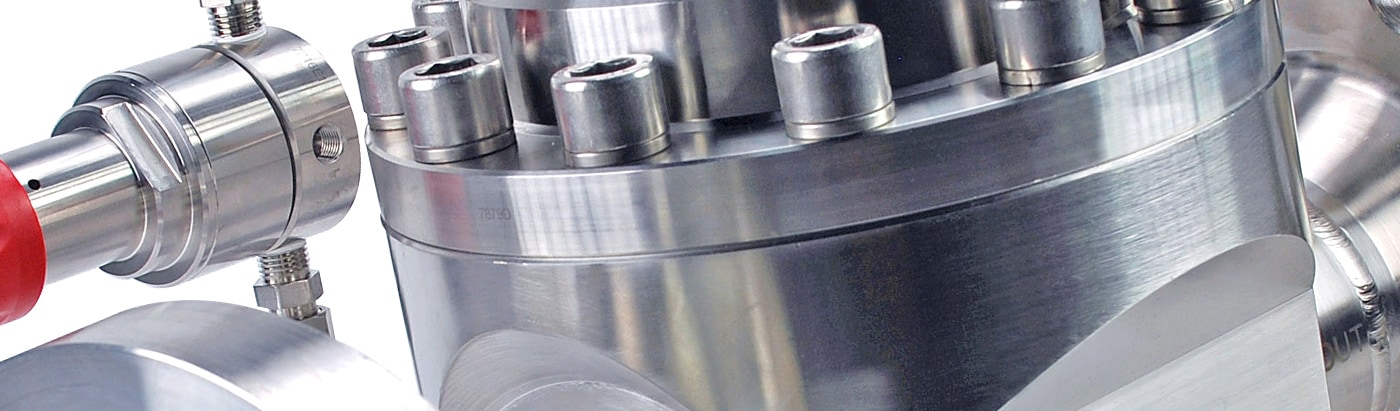

Hilfe bei der Auswahl von DruckreglernDie Druckregler der Serien SGRD und SHRD sind auf maximale Lebensdauer in anspruchsvollen Umgebungen ausgelegt. Das Gehäuse ist aus Edelstahl 316L gefertigt, um eine hohe Korrosionsbeständigkeit und Langlebigkeit zu erreichen. In diesen Reglern sind interne Dichtungen aus unterschiedlichen Werkstoffen verbaut, um eine verbesserte Kompatibilität mit unterschiedlichsten Chemikalien und Druckbedingungen zu gewährleisten.

Dombelastete Druckminderer zeichnen sich durch hohe Leistungsstärke aus, wenn es darum geht, den Ausgangsdruck auf einem stabilen Wert zu halten. Durch die Nutzung eines Doms anstelle einer Feder wird die Regeldifferenz bei diesen Reglern effektiv minimiert. Dank der Auslegung wird ein konsistenter Ausgangsdruck gewährleistet, unabhängig von Schwankungen des Eingangsdrucks oder des Durchflusses.

Merkmale der Serien SGRD und SHRD

- Druckentlasteter Ventilkegel

- Membransteuerung

- Nicht entlüftend

- Pilotgesteuerter Regler

Anpassbare Merkmale

- Externes Feedback an pilotgesteuerten Regler

- Differenzdruckpilotregler (Serie SGRD)

- Zweistufiger Pilotregler (Serie SGRD)

- Manipulationssicherer / werkseitig eingestellter Pilotreglergriff

- NACE MR0175/ISO 15156

Mehr über unterschiedliche Arten von Druckreglern erfahren

Dombelastete Druckminderer für den Einsatz in allgemeinen industriellen Anwendungen (Serie SGRD)

Spezifikationen

| Gehäusegröße | Max. Eingangsdruck psig (bar) | Max. Ausgangsdruck psig (bar) | Einstellbarer Druckbereich psig (bar) | Sensorart psig (bar) | Temperaturbereich °F (°C) | Durchflusskoeffizient (Cv) | Mindestgewicht lb (kg) |

|---|---|---|---|---|---|---|---|

| 12 | 6000 (413) | 6000 (413) | 5 bis 6000 (0,3 bis 413) | Membran: 5 bis 6000 (0,3 bis 413) | –49 bis 356 °F (–45 bis 180 °C) | 2,3 | 9,7 (4,4) |

| 16 | 4,8 | 26,5 (12,0) | |||||

| 24 | 10,7 | 27,6 (12,5) |

Hochempfindliche dombelastete Druckminderer (Serie SHRD)

Spezifikationen

| Gehäusegröße | Max. Eingangsdruck psig (bar) | Max. Ausgangsdruck psig (bar) | Einstellbarer Druckbereich psig (bar) | Sensorart psig (bar) | Temperaturbereich °F (°C) | Durchflusskoeffizient (Cv) | Mindestgewicht lb (kg) |

|---|---|---|---|---|---|---|---|

| 12 | 250 (17,2) | 250 (17,2) | 1 bis 250 (0,07 bis 17,2) | Membran: 1 bis 250 (0,07 bis 17,2) | –49 bis 356 °F (–45 bis 180°C) | 2,3 | 9,7 (4,4) |

| 16 | 4,8 | 26,5 (12,0) | |||||

| 24 | 10,7 | 27,6 (12,5) |

Katalog zu Druckminderern, dombelasteten Druckreglern

Hier finden Sie ausführliche Produktinformationen zu Werkstoffen, Drücken und Temperaturen, Optionen und Zubehör.

Swagelok RHPS series deliver precise pressure control in process fluid systems up to 4 in. (101 mm) in a variety of spring-, dome-, and air-loaded pressure regulators.

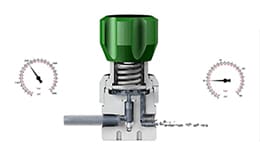

A pressure regulator has a sensing element (piston or diaphragm) which, on one side, is subjected to a load force (FS) created by a spring (as shown below) or gas pressure. On the other side, the sensing element is subject to the force (F) of the system fluid.

Sie brauchen Unterstützung bei der Auswahl der richtigen Druckregler?

Vergleichen Sie die Leistung verschiedener Druckregler unter verschiedenen Anwendungsbedingungen mit unserem Tool zur Erstellung von Durchflussdiagrammen.

Finden Sie den richtigen DruckreglerSwagelok-Ressourcen für Sie zusammengestellt

레귤레이터 내 공급-압력 효과(SPE) 관리

공급-압력 효과(SPE)란 의존성이라고도 부르며, 레귤레이터의 입구 압력과 출구 압력 변화 사이의 반비례 관계를 의미합니다. Swagelok이 제공하는 팁을 통해 압력 레귤레이터에서 이러한 현상을 관리하는 방법을 알아보십시오.

철저한 테스트가 신뢰성 높은 레귤레이터 성능을 보장하는 이유

극한 조건에서 올바르게 작동하도록 제품을 설계하려면 어떤 테스트가 필요할지 궁금하십니까? 영하의 온도에서도 작동하는 Swagelok RHPS 시리즈 산업용 레귤레이터의 개발 과정을 따라가면서 어떻게 설계되는지 알아보십시오.

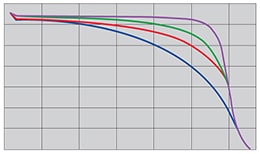

레귤레이터 유량 곡선을 평탄화하여 드룹(droop)을 줄이는 방법

드룹(droop)은 모든 감압 레귤레이터에서 발생하는 공통된 문제입니다. 다양한 돔 하중 레귤레이터 구성을 사용하여 드룹(droop)을 최소화하고 레귤레이터 유량 곡선을 평탄화하는 방법을 알아보십시오.

분석 계장 시스템에서 레귤레이터를 사용하여 시간 지연을 줄이는 방법

시간 지연 문제는 종종 분석 시스템에서 과소 평가되거나 오해를 받습니다. 이러한 문제를 완화하는 방법 중 하나는 압력 제어 레귤레이터를 사용하는 것입니다. 이러한 팁을 통해 분석 시스템의 시간 지연을 관리하는 방법을 알아보십시오.