Swagelok® Regulators

Industrial pressure regulators are vital to ensure the safe operation of fluid systems. Swagelok pressure regulators offer consistent, accurate performance for safe and cost-effective fluid system operation. With global experts and field specialists, Swagelok provides both quality products and essential knowledge to optimize pressure in critical applications, ensuring reliability and support for industrial professionals worldwide.

Discover the Best Regulator For Your NeedsSwagelok pressure regulators offer consistent, accurate, and long-lasting performance for industrial professionals. Swagelok regulators are designed, manufactured, assembled, and tested to rigorous standards, maintaining Swagelok's reputation for uncompromising quality. Our comprehensive portfolio of regulators effectively manages pressure across diverse flow rates and applications, promoting safety, reliability, and cost-efficiency in fluid system operations.

Our product line includes analytical and instrumentation regulators (K series) for precise control in testing environments, process pressure regulators (Process Regulator and RHPS series) for large-scale industrial applications, high-purity high-flow regulators (HF series) for clean processes, vaporizing pressure-reducing regulators (KEV and KSV series) for sample preparation, gas cylinder changeover regulators (KCM series) for continuous gas flow, and tank blanketing regulators for safety in hazardous fluid storage.

Industrial professionals often face pressure control issues due to incorrect product selection. Our advisors possess the technical expertise to assist you with component sizing, material selection, on-site troubleshooting, and system design support. This helps you ensure dependable operation of your pressurized fluid systems. With Swagelok's comprehensive range of regulators and expert support, you can achieve your goals confidently.

Regulators Categories

Back-Pressure Regulators, Dome-Loaded

Safeguard complex systems' sensitive equipment by controlling varying inlet and upstream pressures despite varying flow demands.

Back-Pressure Regulators, Spring-Loaded

Precisely control inlet pressure, ensuring consistent process output and performance across various industrial applications.

High-Purity, High-Flow Gas Regulators, HF Series

Design systems more efficiently with manual adjustability, high-flow capacity, and a corrosion-resistant design for dependable gas control.

Pressure-Reducing Regulators, Dome-Loaded

Achieve precise and consistent control over pressure fluctuations, irrespective of variations in flow rate or inlet pressure.

Pressure-Reducing Regulators, Spring-Loaded

Maintain process outputs within chemical distribution, DI water, and chemical delivery systems with the right pressure-reducing, spring-loaded regulator.

Pressure-Reducing Regulators, Electrically-Heated

Enhance accuracy and stability with an electrically heated vaporizing pressure-reducing regulator, ideal for vaporizing liquid samples or preheating gas samples.

Steam-Heated Vaporizing Pressure-Reducing Regulators

Explore cutting-edge vaporizing pressure reducing regulators at Swagelok. Achieve precise pressure control with our diverse product range.

Gas Cylinder Changeover Regulators

Ensure safe and efficient gas supply with our high-quality gas cylinder regulators and changeover regulators. Trust us for reliable gas control solutions!

Tank Blanketing Pressure Regulators

Explore Swagelok's tank blanketing regulator solutions for precise pressure control and reliable gas management in industrial processes.

Ramp Regulators

Discover Swagelok’s hydrogen pressure regulator for refueling stations. Learn how this hydrogen gas regulator ensures safe, precise pressure control.

Spare Parts and Accessories

Maintain regulators and reduce downtime with OEM rebuild kits. Kits include wetted components, lubricant, and instructions.

Regulators Catalogs

Whether you need to maintain pressure downstream or upstream in an analytical or instrumentation setting (K series) or control pressure in a challenging industrial environment (RHPS series), a high-purity, high-flow application (HF series), or a system with storage tanks containing hazardous fluids (tank blanketing), we have a configuration to meet your needs. Find detailed product information, including materials of construction, pressure and temperature ratings, options, and accessories in the product literature provided here.

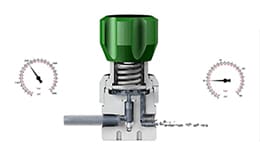

A pressure regulator has a sensing element (piston or diaphragm) which, on one side, is subjected to a load force (FS) created by a spring (as shown below) or gas pressure. On the other side, the sensing element is subject to the force (F) of the system fluid.

Swagelok offers pressure-reducing and vapor recovery (back-pressure) tank blanketing regulators for systems requiring an inert gas in the vapor space of a storage tank.

Features: Compact size with flow rates up to 200 std L/min; Maximum inlet pressures up to 500 psig (34.4 bar); Manually adjustable outlet pressure up to 150 psig (10.3 bar); 316L VIM-VAR stainless steel body for ultrahigh-purity applications; 1/4 in. VCR® metal face seal; 1/4 in. tube butt weld; 1.5 in. and 1.125 in. C-seal and W-seal modular surface-mount end connections

Swagelok® HF series are high-flow, high-purity pressure regulators available in compact preset or dome-loaded models with flow rates up to 300 std L/min.

Swagelok RHPS series deliver precise pressure control in process fluid systems up to 4 in. (101 mm) in a variety of spring-, dome-, and air-loaded pressure regulators.

Swagelok offers pressure-reducing, back-pressure, dome-loaded, and spring-loaded pressure regulators to control pressure and minimize droop in instrumentation systems.

Need Help Selecting the Right Regulators?

Compare the performance of different regulators under varying application conditions with our regulator flow curve generator tool.

Find the Right RegulatorSwagelok Resources Curated for You

Managing Supply Pressure Effect (SPE) in a Regulator

Supply pressure effect, also known as dependency, is an inverse relationship between inlet and outlet pressure variables within a regulator. Learn how to manage this phenomenon in your pressure regulators with tips from Swagelok.

How to Minimize Droop

Droop, or the decrease in outlet pressure as downstream flow increases, can be an issue for all regulators. Watch this video to discover considerations for minimizing droop in a pressure-reducing regulator.

Heated Regulators (KEV Series) Solution Spotlight

Discover how the reliable Swagelok® KEV Series Heated Regulator for analytic sampling systems responds to changes in operator inputs, ambient temperatures, and other operating conditions to deliver consistent, reliable performance.

How to Use a Regulator to Reduce Time Delay in an Analytical Instrumentation System

Time delay is often underestimated or misunderstood in analytical systems. One way to mitigate this delay is with a pressure-controlled regulator. Learn how to manage your analytical system’s time delay with these tips.

From laboratory benches to busy manufacturing facilities and commercial fueling stations, industrial pressure regulators play a crucial role in ensuring fluids are contained and transferred under optimal pressures. If pressure cannot be properly controlled in these applications, test results may be invalidated, processes may be disrupted, equipment may be damaged, and personnel may be put at risk. You need to know the regulators in your system will consistently and accurately maintain pressure levels over extended operating lifespans—all without requiring frequent maintenance, repair, or replacement.

Swagelok pressure regulators provide the consistent, accurate, and lasting performance needed to operate fluid systems safely, reliably, and cost-effectively.

Learn How Regulators Perform

Swagelok has advisors on fluid systems located at authorized sales and service centers around the world to provide local support in choosing between a spring-loaded, a dome-loaded, or one of the many other available regulator configurations. These advisors can also help diagnose regulator problems and customize and build fluid systems that include regulators such as a gas distribution system.

Find out more about these services as well as related training classes available from Swagelok