世伟洛克热塑软管在与液压泵和球阀一起使用时可提供强大的耐压力脉冲性能。由于这些软管具有耐高压变化的特性,因此在 CNG 车辆燃料加注应用中表现尤为出色,而且这些软管还通过了 NGV 和 ECE R110 替代燃料认证。

我们的高性能多用途光滑内孔尼龙内芯软管可通过各种端接快速、安全地连接液压、天然气和其他一般工业应用。光滑的内壁可提供流量控制和增强的排水性,以实现所需的精确度和清洁度,而聚氨酯外层则耐磨损。

世伟洛克聚乙烯软管内管材料符合 FDA 21 CFR 第 177 1520 部分和 NSF-51 标准,是食品、乳制品和水应用中的可靠选择。内部纤维编织加强层提高了承压能力和灵活性。聚氨酯外层抗磨损,并防止水分滞留和系统污染。

是否需要热塑软管选型方面的帮助?

Thermoplastic Hose Categories

End Connections

Enable easy field installation of Swagelok® hoses by selecting from a variety of end connections in a range of sizes.

Nylon Hose

Use the 7R and 8R Series nylon hose in hydraulic applications where outgassing is a concern.

Polyethylene Core Hose

Ensure FDA compliance and prevent system contamination in food, dairy, and water applications with Swagelok's polyethylene core hose.

软管和柔性卡套管样本

查找详细的产品信息,包括结构材料、额定压力和温度、选购件及配件。

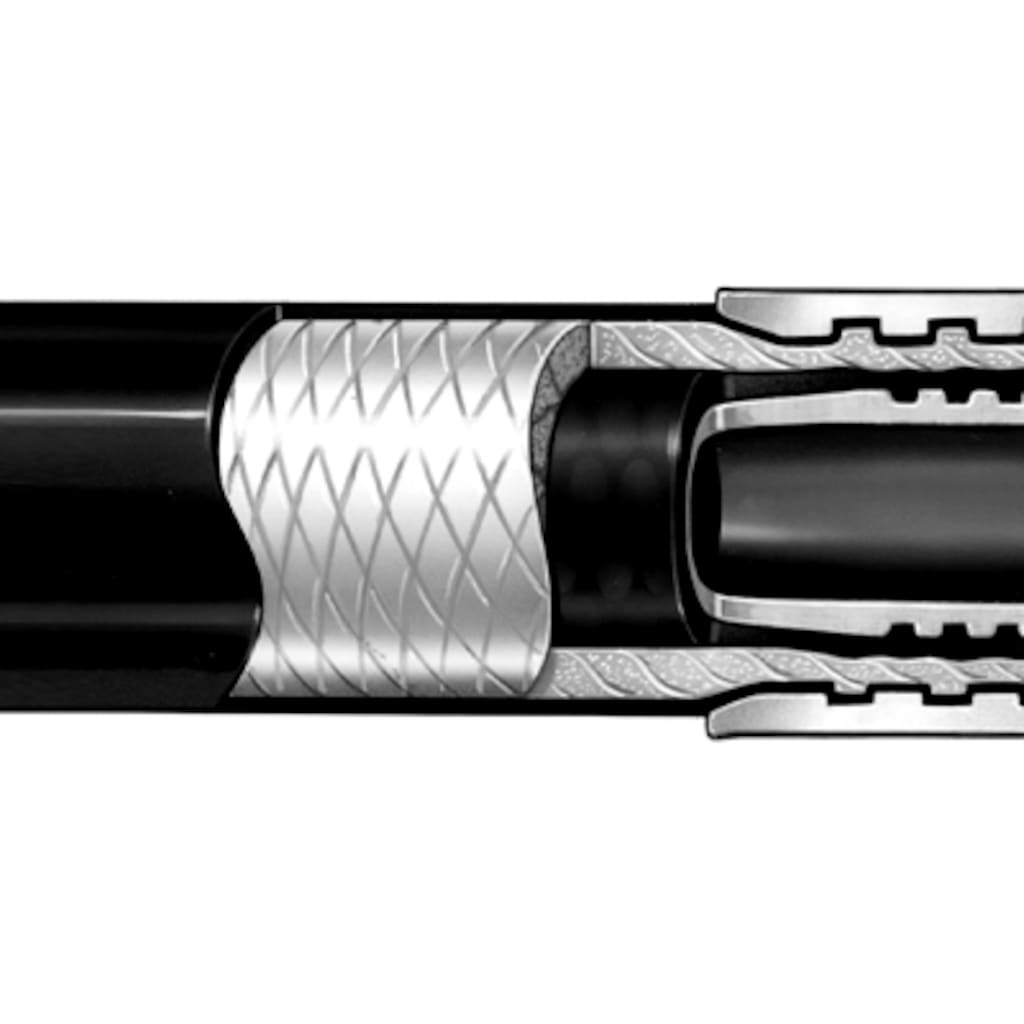

Swagelok® hose and tubing products are available in custom lengths, in diameters 2 inches and under, and with many types of end connections, core materials, and reinforcement styles to suit a broad spectrum of pressures and temperatures.

世伟洛克为您精心准备的产品、服务和解决方案

提高软管安全性并降低工厂成本的三个步骤

在工厂定期维护期间,人们通常不太重视工业软管的安全性。软管的泄漏和磨损会导致您的设备处于风险中,应该得到重视。了解避免危险状况同时降低工厂成本的建议。

工业软管维护计划如何为您的工厂节省大笔费用

了解更换工业软管的适当时机可以为您工厂节省大量维护成本。了解如何评估您的系统并制定预防性维护计划以管理软管的生命周期。

工业软管更换:内管材料注意事项

在选择工业软管时,首先要考虑内管,即软管最内层。通过世伟洛克专家提供的内管材料和管壁构造信息,了解如何为您的应用选择理想的软管。

如何选择正确的软管加强

工业软管通常包含有助于延长使用寿命和提高性能的关键加强层。了解不同的加强层类型,以及适合不同流体系统应用的加强层类型。