Swagelok® Steam-Heated Vaporizing Pressure-Reducing Regulators

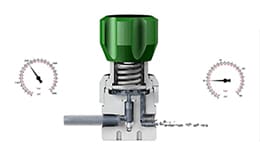

The KSV series steam-heated vaporizing regulator is designed to vaporize liquid samples and preheat gas samples.

Get Help Selecting RegulatorsSwagelok’s steam-heated vaporizing pressure-reducing regulator is designed to effectively vaporize liquid samples or warm gas samples, preventing condensation. It is engineered to adapt to changes in user inputs, ambient temperatures, and other operating conditions. Certified for use in critical and hazardous environments, KSV series regulator consistently delivers dependable performance.

Key Features of the KSV Series Regulator

- Convoluted, nonperforated diaphragm

- Metal-to-metal diaphragm seal

- Low internal volume

Specifications

| Maximum Inlet Pressure | 3600 psig (248 bar) |

| Pressure Control Ranges | 0 to 10 psig (0.68 bar) through 0 to 500 psig (34.4 bar) |

| Flow Coefficient (Cv) | 0.06 or 0.20 |

| Maximum Steam Pressure and Temperature | 650 psig (44.7 bar) and 500°F (260°C) |

| Maximum Operating Temperature | 392°F (200°C) |

蒸気加熱式減圧レギュレーターのカタログ

蒸気加熱式減圧レギュレーターの構成部品とその材質、アクセサリー、使用圧力、使用温度など、製品に関する詳細情報につきましては、以下の資料をご参照ください。

Swagelok offers pressure-reducing, back-pressure, dome-loaded, and spring-loaded pressure regulators to control pressure and minimize droop in instrumentation systems.

関連資料/コラム記事

レギュレーターの供給圧力影響(SPE)に対処する

レギュレーター内部における一次側圧力の変化と二次側圧力の変化は、供給圧力影響(SPE)または依存性による反比例の関係にあります。今回は、圧力レギュレーターで発生する供給圧力影響(SPE)による現象への対処方法を紹介します。

レギュレーターの信頼性を確保するために

過酷な条件下での運用を前提とした製品には、どのような試験を行うべきでしょうか。今回は、スウェージロックの実験室における取り組みと共に、氷点下を大幅に下回る温度でも正常に機能する一般産業用RHPSシリーズ・レギュレーターの開発事例を紹介します。

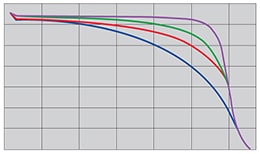

レギュレーターの流量曲線を平坦にしてドループを抑える方法

ドループ(流量増加に伴う二次側圧力の降下)は、あらゆるレギュレーターに共通する問題です。今回は、ドループを最小限に抑えてレギュレーターの流量曲線を平坦にする方法を、さまざまなドーム・ロード式レギュレーターの構成と併せて紹介します。

レギュレーターを使用して分析計装システムにおける時間遅れを短縮する方法

分析システムでは、時間遅れが軽視されていたり、誤解されていたりするケースは少なくありません。この時間遅れは、レギュレーターでコントロールすることができます。今回は、分析計装システムにおける時間遅れを小さくする方法を紹介します。