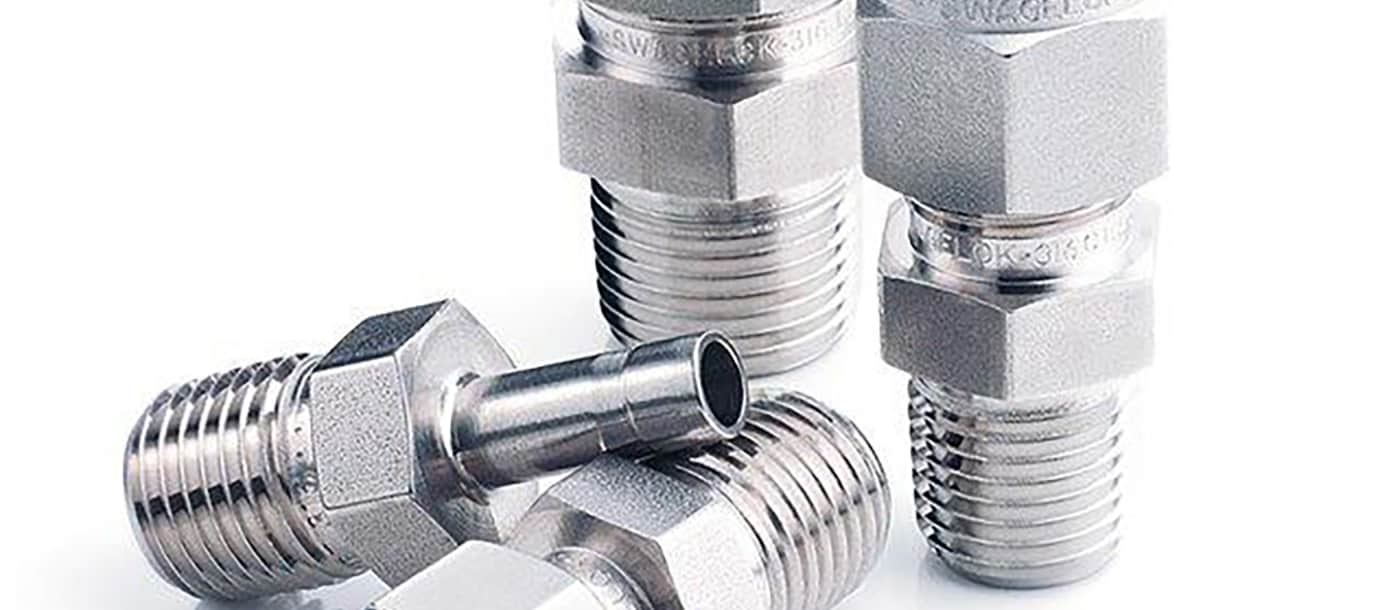

高純度用PFA製フレアー継手

Swagelok®PFA製フレアー継手を使用すると、高純度アプリケーションにおいて流体システムの安全かつ効率的なオペレーションを実現することができます。半導体製造や反応性の高い化学物質を取り扱う環境での使用に適しています。

PFA製フレアー継手の選定サポートを依頼するSwagelok®PFA製フレアー継手は、フルオロポリマーから成形されています。引張強さ、耐透過性、熱安定性 を備えており、過酷な流体システムにおいても漏れの無い接続を維持します。Swagelok PFA製フレアー継手は、その他の互換性がある超高純度用製品(バルブやチューブなど)と組み合わせることで、反応性の高い流体を取り扱う統合システムを構築することが可能です。ストレート型、エルボー型、ティー型をはじめ、さまざまな形状やサイズを取り揃えています。アプリケーションのニーズに合わせて、PFA製ボディとPVDF製ナットの組み合わせ(標準)に加えて、PFA製ボディとナット、PVDF製ボディとナットの組み合わせを選ぶことができます。

仕様

| 最高使用圧力 | 1.89 MPa |

| 使用温度範囲 | 23~176°C |

| ボディ材質 | 高純度PFA |

| ナット材質 | PVDF(標準)、PFA(オプション) |

| エンド・コネクション | サイズ:1/8~1 インチ 構成:ストレート型、エルボー型、ティー型、キャップ、プラグ、ナット |

高純度用PFA製フレアー継手のカタログ

構成部品とその材質、使用圧力、使用温度、オプション、アクセサリーなど、製品に関する詳細情報につきましては、以下の資料をご参照ください。

Features: Available in 1/4, 3/8, 1/2, 3/4 and 1 in. tube sizes; PFA and PVDF nut options; A wide variety of configurations

継手の基礎:ねじのサイズとピッチを識別する

経験豊かなベテランでも、ねじを識別するのは容易ではありません。今回は、継手のねじのサイズとピッチを、ノギス、ねじピッチ・ゲージ、ねじ識別ガイドで識別する方法を紹介します

継手の選定に関する詳細を見る関連資料/コラム記事

最先端科学で信頼できる流体システム・ソリューション

フィンランドの希釈冷凍機メーカーであるブルーフォース社が、量子コンピューターや実験物理学などに欠かせない流体システム部品やソリューションに関して、スウェージロックに信頼を寄せている理由を紹介します。

収益性が高い半導体ファブを建設するために

高品質な流体システム部品やアセンブリーを選定することで、半導体ファブの建設に要する時間の短縮と、施設のライフサイクル・コスト削減が実現する理由について紹介します。

最適な合金で半導体製造の歩留まりを高める

重要な流体システム部品に適した金属材料を選定することで、エンドからエンドまでの製造の歩留まりを高め、長期的な収益性の向上を図る方法を紹介します。

Q&A:半導体製造の過去・現在・将来

半導体装置メーカー、マイクロデバイス・メーカー、流体システム・ソリューションのプロバイダーが連携することで、数十年間にわたっていかにして半導体市場はムーアの法則の要求に追いつくことができたのでしょうか。これからの展望と併せて紹介します。