Swagelok® High-Purity, High-Flow Gas Regulators (HF Series)

HF series regulators deliver precise pressure control with easy adjustments, ideal for high-flow and clean process demands.

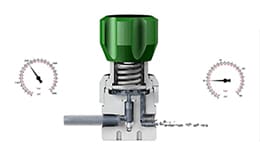

Get Help Selecting RegulatorsHF series regulators are designed for high-flow systems, allowing for compact arrangement of system components and process lines. The gas-actuated models are notably smaller than traditional diaphragm-operated pressure regulators, offering a design that prevents tampering and simplifies installation.

These regulators are engineered for environments demanding high levels of cleanliness. Offering durable and precise pressure control, the HF series includes an innovative pressure-sensing assembly that minimizes supply pressure effects and droop, often removing the need for system adjustments.

They feature tied poppets for clean operation and secure shutoff, while an all-welded design eliminates atmospheric seals. Self-centering PCTFE poppets help prevent creep and ensure a leak-tight seal.

HF series regulators also feature:

- Ability to handle maximum inlet pressures up to 3000 psig (206 bar)

- Manually adjustable outlet pressure up to 150 psig (10.3 bar)

- 316L VIM-VAR stainless steel body for ultrahigh-purity applications

- 1/4 in. VCR® split-nut; 1/4 and 3/8 in. tube butt weld; 1.5 in. and 1.125 in. modular surface-mount end connections

High-Purity, High-Flow Gas, HF Series Regulators Catalogs

Locate detailed product information, including materials of construction, pressure and temperature ratings, options, and accessories.

Features: Compact size with flow rates up to 200 std L/min; Maximum inlet pressures up to 500 psig (34.4 bar); Manually adjustable outlet pressure up to 150 psig (10.3 bar); 316L VIM-VAR stainless steel body for ultrahigh-purity applications; 1/4 in. VCR® metal face seal; 1/4 in. tube butt weld; 1.5 in. and 1.125 in. C-seal and W-seal modular surface-mount end connections

Swagelok® HF series are high-flow, high-purity pressure regulators available in compact preset or dome-loaded models with flow rates up to 300 std L/min.

Need Help Selecting the Right Regulators?

Learn more about different types of regulators under varying application conditions with our regulator selection video.

Find the Right RegulatorSwagelok Resources Curated for You

Managing Supply Pressure Effect (SPE) in a Regulator

Supply pressure effect, also known as dependency, is an inverse relationship between inlet and outlet pressure variables within a regulator. Learn how to manage this phenomenon in your pressure regulators with tips from Swagelok.

How Thorough Testing Ensures Reliable Regulator Performance

Have you ever wondered what testing goes into a product designed to operate in extreme conditions? Take a look behind the lab doors, following the development journey of RHPS Series industrial regulators rated for use at temperatures well below zero.

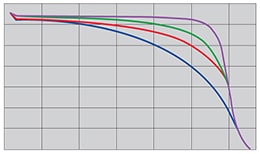

How to Flatten a Regulator Flow Curve to Reduce Droop

Droop is an issue for every pressure-reducing regulator. Learn how to minimize droop and flatten regulator flow curves with various dome loaded regulator configurations.

How to Use a Regulator to Reduce Time Delay in an Analytical Instrumentation System

Time delay is often underestimated or misunderstood in analytical systems. One way to mitigate this delay is with a pressure-controlled regulator. Learn how to manage your analytical system’s time delay with these tips.