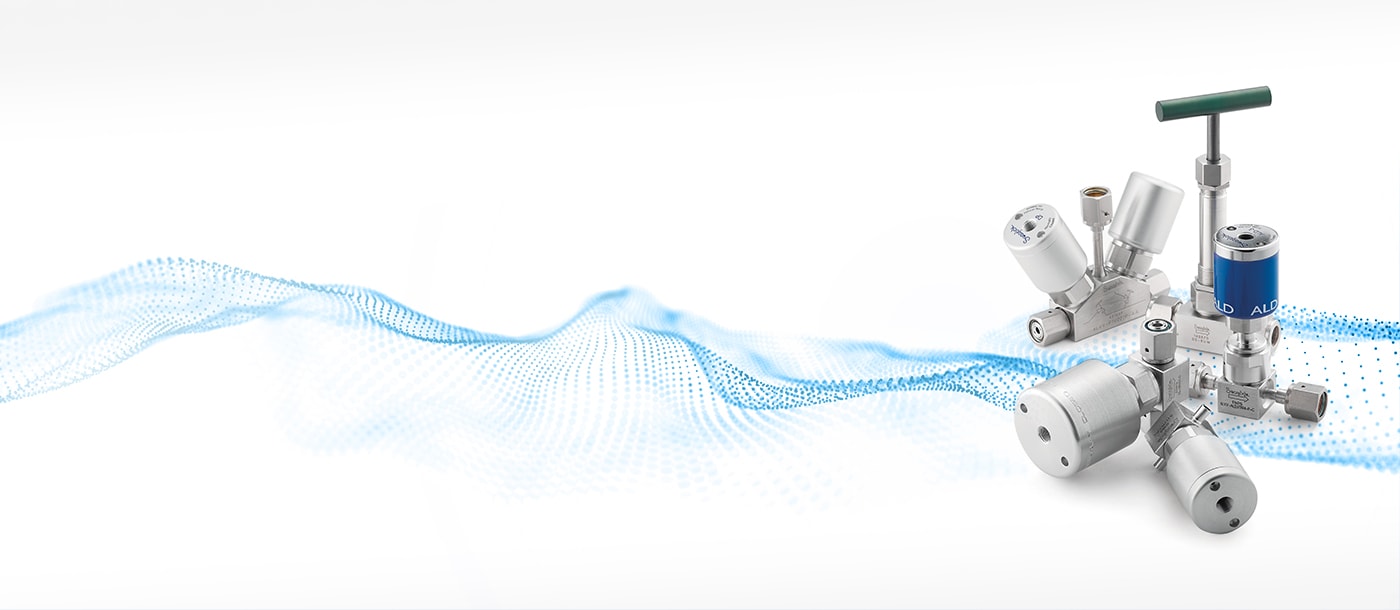

用于原子层沉积工艺的世伟洛克®超高纯隔膜阀(ALD7 系列)

世伟洛克 ALD7 超高纯阀提供了在新的或已有的半导体制造设备中,帮助尽可能地提高芯片产量所必需的流量一致性和流通能力、执行机构速度、温度等级和洁净度。

索取 ALD7 阀门信息The Swagelok® ALD7 ultrahigh-purity diaphragm valve for atomic layer deposition (ALD) processing enables semiconductor tool manufacturers and chip fabricators to increase viable chip yields and enhances profitability by enabling the flow consistency and capacity, actuator speed, and performance at high temperatures necessary to overcome production processes limitations. It provides consistent performance from valve to valve, dose to dose, and chamber to chamber over an ultrahigh cycle life.

The Swagelok ALD7 valve:

- Delivers quick, precise dosing over the course of millions of cycles in even the most demanding applications and features enhanced actuator technology with a response time as low as 5 ms

- Is resistant to corrosive gases with a valve body comprised of proprietary ultrahigh-purity Swagelok 316L VIM-VAR stainless steel

- Can be heated up to 200°C while keeping the pneumatic actuator below maximum operating temperature of 150°C

- Delivers a flow coefficient (Cv) up to 0.7 (with optional custom (factory-set) versions available that deliver a flow coefficient of 0.5–0.7 Cv)

- Maintains the same footprint as Swagelok industry-standard ALD valves and features an integrated thermal isolator to maximize limited space near the reaction chamber

ALD7 Valve Specifications

| Working Pressure | Vacuum to 145 psig (10.0 bar) |

| Burst Pressure | >3200 psig (220 bar) |

| Actuation Pressure | 60 to 120 psig (4.1 to 8.27 bar) |

| Temperature Rating | Standard valve body from 32°F (0°C) to 392°F (200°C) |

| Flow Coefficient | Standard 0.7 Cv (factory set) |

| Body Materials | 316L VIM-VAR stainless steel |

| Diaphragm Material | Cobalt-based superalloy |

| End Connections | Type: VCR® fittings, tube butt weld, 1.5 in. modular surface-mount high flow C-seal |

Have questions about ALD valves?

ALD7 Series Valves Catalogs

Locate detailed product information, including materials of construction, pressure and temperature ratings, options, and accessories.

原子层沉积 (ALD) 隔膜阀,高速执行下的超高循环寿命 ,Cv 0.27 到 0.62,耐热执行器, 耐温高达 200°C(392°F),电子执行器位置传感选购件,合采用 316L VIM-VAR 不锈钢阀体的超高纯应用场合,VCR®, 卡套管对焊和模块化表面安装端接

Swagelok Resources Curated for You

利用优化的合金提高半导体制造良率

了解半导体制造商如何通过为关键流体系统组件选择合适的金属材料,提高端到端制造良率并提高长期盈利能力。

问答:半导体制造的过去、现在与未来

了解半导体OEM设备商、微芯片制造商与流体系统解决方案提供商之间的协作如何使半导体市场在数十年来能够满足摩尔定律的要求以及未来的发展方向。

Производитель оптоволоконного оборудования повышает эффективность с помощью индивидуальных решений

С 1980-х годов Rosendahl Nextrom полагается на компанию Swagelok в развитии своего бизнеса. Узнайте больше о решениях, которые позволили компании опередить конкурентов и остаться в числе отраслевых лидеров.

Reliable Fluid System Solutions for the Scientific Frontier

Learn why Finnish dilution refrigerator manufacturer Bluefors trusts Swagelok for fluid system components and solutions that help enable quantum computing, experimental physics, and more.