世伟洛克® 调压阀

工业调压阀对于确保流体系统的安全运行至关重要。世伟洛克调压阀具有稳定、精确的性能,可确保流体系统安全且经济高效地运行。世伟洛克拥有全球专家和现场专家,可提供优质产品和基本知识,以优化苛刻应用中的压力,确保可靠性,并为全球工业专业人员提供支持。

了解满足您需求的合适调压阀世伟洛克调压阀为工业专业人员提供稳定、精确和持久的性能。世伟洛克调压阀的设计、制造、装配和测试均符合严格的标准,从而保持了世伟洛克在质量方面毫不妥协的声誉。我们全面的调压阀产品组合可有效管理各种流速和应用的压力,从而提高流体系统运行的安全性、可靠性和成本效益。

我们的产品系列包括:用于测试环境中精确控制的分析和仪器调压阀(K 系列)、用于大规模工业应用的工艺调压阀(工艺调压阀和 RHPS 系列)、用于清洁工艺的高纯度高流量调压阀(HF 系列)、用于样品制备的汽化减压调压阀(KEV 和 KSV 系列)、用于连续气流的气瓶切换调压阀(KCM 系列)以及用于危险流体储存安全的罐封调压阀。

工业专业人员经常会因产品选择不当而面临压力控制问题。我们的顾问拥有专业技术知识,可以在组件尺寸、材料选择、现场故障排除和系统设计支持等方面为您提供帮助。这有助于您确保压力流体系统的可靠运行。有了世伟洛克种类齐全的调压阀和专家支持,您就能满怀信心地实现自己的目标。

调压阀类别

Ramp Regulators

Discover Swagelok’s hydrogen pressure regulator for refueling stations. Learn how this hydrogen gas regulator ensures safe, precise pressure control.

调压阀样本目录

无论您是需要在分析或仪表环境中保持下游或上游的压力(K 系列),还是需要在具有挑战性的工业环境中控制压力(RHPS 系列),是在高纯度、高流量的应用(HF 系列),还是在含有危险液体的储罐系统(罐封),我们都有满足您需求的配置。在这里提供的产品资料中查找详细的产品信息,包括结构材料、额定压力和温度、选购件及附件。

Swagelok offers pressure-reducing and vapor recovery (back-pressure) tank blanketing regulators for systems requiring an inert gas in the vapor space of a storage tank.

结构设计紧凑,流量达 200 std L/min, 最大进口压力达 500 psig (34.4 bar), 手动可调的出口压力达 150 psig (10.3 bar), 316L VIM-VAR 不锈钢阀体用于超高纯应用, 1/4 in. VCR® 金属面密封;1/4 in. 卡套管对焊;1.5 in. 和 1.125 in. 封模块化表面安装端接

减压型, 背压型, 弹簧, 圆顶和空气加载, 1/4 至 4 in. 端接, 工作压力可达 10 150 psig (700 bar), 温度–20 至 80°C(–4 至 176°F)

世伟洛克为您精心准备的产品、服务和解决方案

管理调压阀的供压效应 (SPE)

供压效应也称依赖性,是指调压阀中的进口压力变化与出口压力变化之间互为反比关系。了解如何根据世伟洛克的建议管理调压阀中的这种现象。

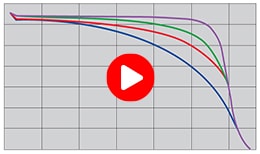

如何尽可能减少压力衰减

压力衰减,即出口压力随着下游流量增大而减小,对所有调压阀而言都是一个问题。观看本视频,了解在减压阀中尽可能减少压力衰减的注意事项。

加热调压阀(KEV 系列)解决方案聚焦

了解可靠的世伟洛克® KEV系列分析取样系统加热调压阀如何对操作人员输入、环境温度和其他工作条件的变化做出反应,从而提供一致、可靠的性能。

如何使用调压阀来降低分析仪器系统中的延时

在分析系统中,延时常常被低估或误解。降低这种延时的一种方法是使用压力控制调压阀。了解如何通过这些技巧来管理分析系统的延时。

从实验室工作台到繁忙的制造设施和商业化的加气站,工业调压阀在确保流体在合适压力下被容纳和传输方面发挥着关键作用。如果在这些应用中不能妥善控制压力,测试结果可能无效,工艺可能中断,设备可能损坏,人员可能处于危险之中。您需要知道您系统中的调压阀能够在较长的工作寿命内始终精确地保持压力水平—所有这些都不需要频繁的维护、修理或更换。

世伟洛克调压阀具有安全、可靠、经济高效地操作流体系统所需的一致、准确和持久的性能。

了解调压阀如何工作

世伟洛克在世界各地的授权销售与服务中心都有流体系统专家,在选择弹簧加载式、圆顶加载式或其他许多可用的调压阀配置时提供当地支持。这些专家还可以帮助诊断调压阀问题,并定制和建立包括调压阀在内的流体系统,如气体分配系统。