スウェージロックの潤滑剤

Swagelok Goop™ ねじ潤滑剤を使用すると、各種金属製および合金製のねじを容易に取り付けることができるため、取り付け時間を短縮でき、漏れの無いシステムを構築することができます。

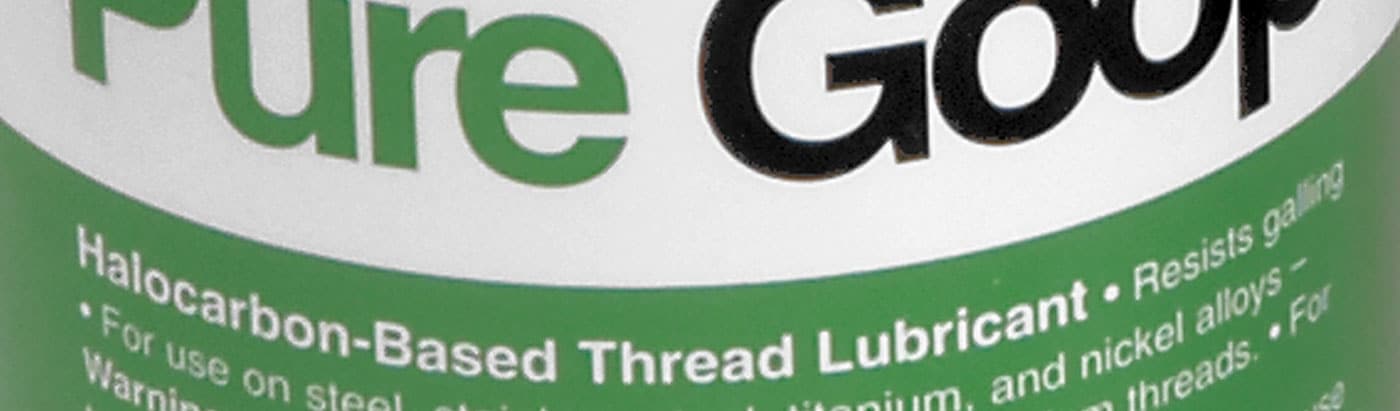

潤滑剤を見るSwagelok Goop™ねじ潤滑剤を使用すると、漏れの無い接続部を迅速かつ容易に構築することができます。Swagelok Goopにはオイル・ベース、ハロカーボン・ベース、フルオロシリコーン・ベースの製品があります。さまざまな材質のねじ、そして真空システムをはじめとする幅広いアプリケーションに使用されています。

- Silver Goop(シルバー・グープ)は、オイル・ベースのねじ潤滑剤で、ステンレス鋼および耐熱合金に使用できます。かじりを防止し、非融解性焼き付き防止剤を含有しています。ねじ部のトルクを低減し、応力が加わっても接合表面に定着します。

- Pure Goop(ピュア・グープ)はハロカーボン・ベースのねじ潤滑剤で、チタニウム、ステンレス鋼、炭素鋼、ニッケル基合金に使用できます。かじりを低減し、耐湿性を有しています。さまざまな材質に対し化学反応を起こしません。

- Blue Goop(ブルー・グープ)はオイル・ベースのねじ潤滑剤で、ステンレス鋼、炭素鋼、チタニウム、アルミニウム、ニッケル基合金に使用できます。かじりを低減し、水によって流失しません。色は濃いブルーで、水の影響を受けません。

- Vac Goop(バック・グープ)はフルオロシリコーン・ベースのねじ潤滑剤で、真空システム内のねじ、Oリング、ガスケット、ガラス・シール、金属製部品に使用できます。かじりを低減すると共に、蒸気圧が極めて低いためガスの放出を低減します。さまざまな材質に対し化学反応を起こしません。

ねじ潤滑剤に関して質問がありますか?

潤滑剤のカタログ

構成部品とその材質、使用圧力、使用温度、オプション、アクセサリーなど、製品に関する詳細情報につきましては、以下の資料をご参照ください。

圧縮ガス漏れ検出サービス

圧縮ガスの漏れを特定して数値化することで、排出物の削減、安全性、コスト、生産性の向上などに基づいて、重要な問題から優先して取り組むことができます。

漏れ検出サービスの詳細を見る関連資料/コラム記事

漏れ検出の導入事例

スウェージロックの流体システム専門スタッフは、技術的およびアプリケーションに関する豊富な知識を持っており、流体システムにおける漏れを検出、排除、防止するサポートを定期的に行っています。お客さまが得たメリットを紹介します。

流体システムの漏れの一般的な原因とコスト

プラントのメンテナンス担当者として安全性と収益性を考えるなら、ごくわずかな漏れであっても問題視すべきです。だからこそ、漏れが発生する原因とメカニズム、漏れの発生場所を特定して検査する方法、さらに最終的にはプラント全体で漏れを削減する方法を策定することが有益といえます。

タイヤ工場における一般的な流体システムの漏れに対処する

タイヤの製造工程でプロセス配管の漏れが看過されているケースがありますが、システムに漏れがあると、安全上深刻な問題が生じたり、収益が低下したりするおそれがあります。今回は、工場全体の一般的な漏れの原因を特定する方法と、それを改修する方法を紹介します。

システムの漏れを防ぐ方法:チューブの適切な前処理の重要性

チューブ継手を正しく取り付けるには、さまざまな要素を考慮する必要がありますが、最も重要なのは、取り付ける前にチューブに適切な前処理を施すことです。今回は、チューブを正しく取り扱い、適切に切断してバリを除去し、漏れによるコストとリスクの上昇を抑える方法を紹介します。