世伟洛克® 减压调压阀,圆顶加载

一般工业用(SGRD 系列)和高灵敏度(SHRD 系列)减压型圆顶加载调压阀适用于需要手动或远程操作调压阀和需要精确设定压力控制的各种工业应用。

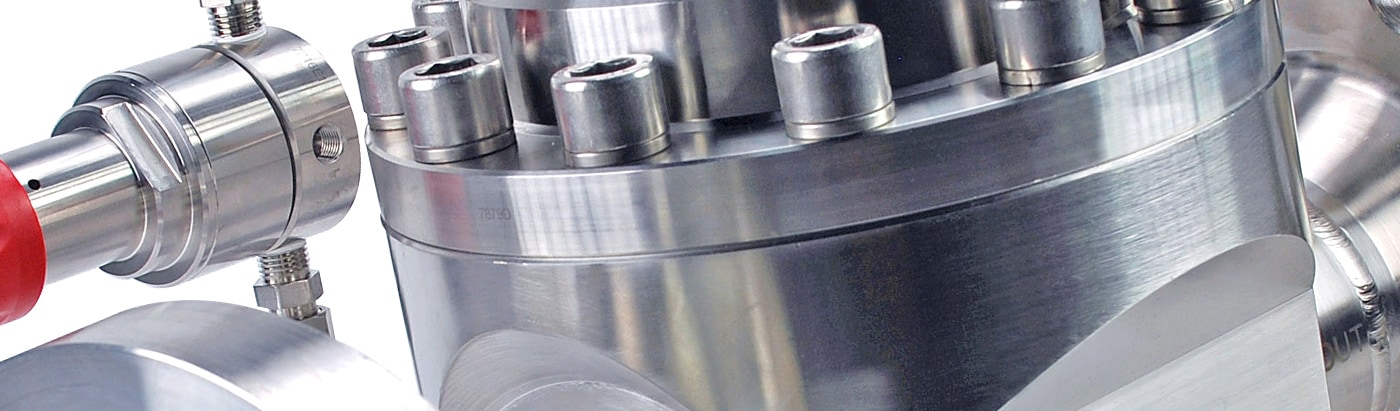

获取工艺调压阀选型的帮助SGRD 和 SHRD 系列调压阀经过精心设计,可确保在苛刻的环境中经久耐用。其阀体由 316L 不锈钢制成,具有更强的耐腐蚀性,使用寿命更长。这些调压阀的内部密封有多种材料可供选择,从而提高了与各种化学品和不同压力条件的兼容性。

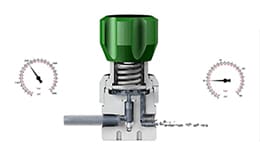

减压型圆顶加载调压阀在保持稳定出口压力方面性能卓越。这些调压阀利用压力圆顶代替设置弹簧进行控制,从而有效地减少了衰减。无论进口压力如何波动或流量如何变化,这种设计都能确保一致的出口压力。

SGRD 和 SHRD 系列特点

- 平衡提升阀芯

- 隔膜传感

- 无排放

- 先导调压阀控制

可定制功能

- 外部反馈至先导调压阀

- 压差先导调压阀(SGRD 系列)

- 双级先导调压阀(SGRD 系列)

- 抗干扰/出厂设置先导阀手柄

- NACE MR0175/ISO 15156

一般工业用减压型圆顶加载调压阀(SGRD 系列)

规格

| 阀体尺寸 | 最大进口压力 psig (bar) | 最大出口压力 psig (bar) | 可调压力范围 psig (bar) | 传感类型 psig (bar) | 温度范围 °F (°C) | 流量系数 (Cv) | 最小重量 lb (kg) |

|---|---|---|---|---|---|---|---|

| 12 | 6000 (413) | 6000 (413) | 5 至 6000(0.3 至 413) | 隔膜: 5 至 6000(0.3 至 413) | —49 至 356° (—45 至 180°) | 2.3 | 9.7 (4.4) |

| 16 | 4.8 | 26.5 (12.0) | |||||

| 24 | 10.7 | 27.6 (12.5) |

高灵敏度减压型圆顶加载调压阀(SHRD 系列)

规格

| 阀体尺寸 | 最大进口压力 psig (bar) | 最大出口压力 psig (bar) | 可调压力范围 psig (bar) | 传感类型 psig (bar) | 温度范围 °F (°C) | 流量系数 (Cv) | 最小重量 lb (kg) |

|---|---|---|---|---|---|---|---|

| 12 | 250 (17.2) | 250 (17.2) | 1 至 250 (0.07 至 17.2) | 隔膜: 1 至 250 (0.07 至 17.2) | —49 至 356° (—45 至 180°) | 2.3 | 9.7 (4.4) |

| 16 | 4.8 | 26.5 (12.0) | |||||

| 24 | 10.7 | 27.6 (12.5) |

减压型圆顶加载工艺调压阀产品目录

查找详细的产品信息,包括结构材料、额定压力和温度、选购件及配件。

调压阀RHPS 系列

减压型, 背压型, 弹簧, 圆顶和空气加载, 1/4 至 4 in. 端接, 工作压力可达 10 150 psig (700 bar), 温度–20 至 80°C(–4 至 176°F)

世伟洛克为您精心准备的产品、服务和解决方案

管理调压阀的供压效应 (SPE)

供压效应也称依赖性,是指调压阀中的进口压力变化与出口压力变化之间互为反比关系。了解如何根据世伟洛克的建议管理调压阀中的这种现象。

全面的测试如何确保可靠的调压阀性能

您是否想知道设计用于在极端条件下运行的产品需要接受哪些测试?跟随用于零度以下环境的RHPS系列工业调压阀的开发之旅,让我们来看看实验室的情况。

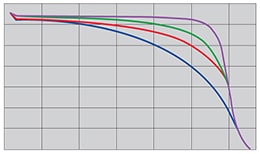

如何使调压阀流量曲线更平稳以减少压力衰减

压力衰减是每个减压阀都难以避免的问题。了解如何利用各种圆顶加载调压阀配置,尽可能地减少压力衰减并使调压阀流量曲线更平直。

如何使用调压阀来降低分析仪器系统中的延时

在分析系统中,延时常常被低估或误解。降低这种延时的一种方法是使用压力控制调压阀。了解如何通过这些技巧来管理分析系统的延时。