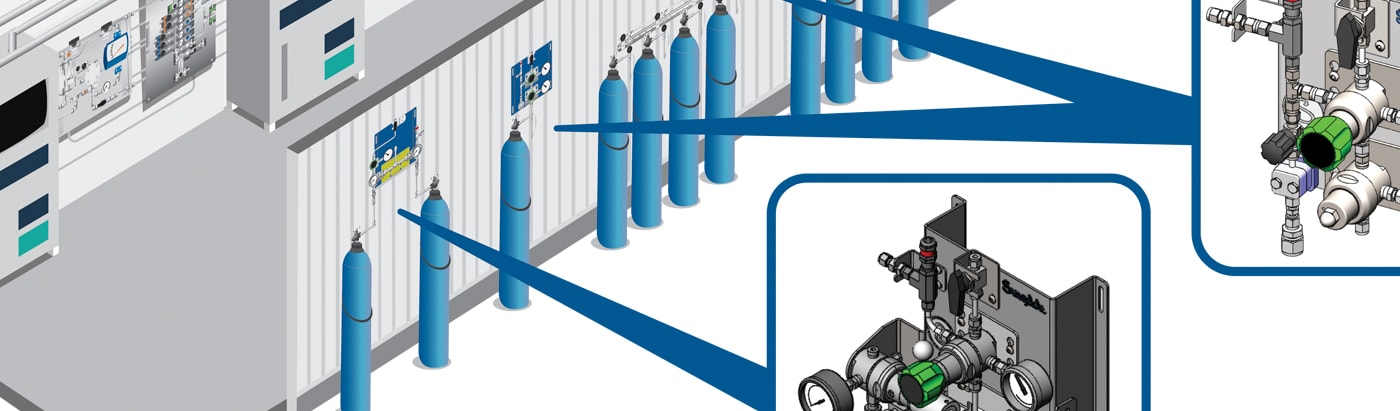

世伟洛克® 气体分配系统

气体分配是许多工业、研究和生产设施的关键功能。安全、可靠、有效地将气体输送到需要的地方,是高效运营的基础。气体分配系统的作用是按每种应用所需的压力和流量,将气体从高压源输送到设施中。

联系专家世伟洛克标准气体分配面板是完全组装和测试好的。它们的订购可以很容易地从我们的应用指南中以单个零件编号的形式完成,从而尽可能地减少您的工程师在规范和采购新系统上花费的时间。

世伟洛克模块化面板采用尽可能少的螺纹连接,以减少潜在的泄漏点,而且它们都有直观的标签,以增强安全性、易用性和可维护性,并由世伟洛克终身有限质保提供支持。

世伟洛克气体分配系统是围绕一个或一系列压力调节步骤而建立的,可能包括四个子系统:

世伟洛克®气源进气口 (SSI)

气源进气口在高压气源和分配系统之间建立连接。重要的是,进气口要建立适当的钢瓶连接、软管、卡套管、过滤器,以及排气、吹扫和泄压功能,以确保气体能够安全地输入到初级气体压力控制或自动切换装置中。对于单个钢瓶,组装可以简单到只需一根软管和一个接头,而多个钢瓶可能需要一个包含许多软管和阀门的歧管。世伟洛克提供在更换气瓶时进行气体吹扫或排放的高度可配置选购件,始终确保操作人员的安全,还可提供对单个管路进行排放的选购件,以尽可能地延长正常运行时间。

世伟洛克顾问将确保所有的部件都包括在内,并正确指定较小的连接点,确保软管不会掉到地上,且部件得到妥善支撑。此外,当某些气体可能需要使用特殊软管时,我们可以提供建议。

世伟洛克®气体面板 (SGP)

SGP 可完成源气体的首次减压,并确保以正确的流速将气体输送到系统的下一级。减压可以通过单个减压阀以单级减压或通过双级减压阀的两级减压的形式实现。

世伟洛克提供易于维修的模块化面板,因为任何部件都可以通过世伟洛克连接拆卸,因此面板无需拆卸,还可根据现场需要在调压阀和阀门周围提供颜色编码选购件。世伟洛克还可以帮助您了解哪些地方需要使用双级调压阀。

世伟洛克®切换装置 (SCO)

自动切换系统可从一个气源无缝切换到另一个气源,以确保不间断供应。这是通过两个调压阀的交错设定点实现的,从而使系统在更换主要气源时可以继续运行。切换站允许指定切换设定点,以减少气瓶中剩余气体的浪费。

世伟洛克可为切换点保持恒定提供更多保证,如果您的系统在下游安装了使用点调压阀,还可以提供可选的管线调节功能,这可以消除在 SCO 上安装调压阀的额外成本。世伟洛克专家可帮助您的团队更好地了解系统功能、排除故障和维护操作。

世伟洛克®使用点 (SPU)

使用点在使用气体前提供关键的压力控制的最后阶段。这些系统通常带有调压阀、压力表和隔离阀。使用点系统提供了一种方便而准确的压力调节方法,以满足试验台或设备的需求。

世伟洛克可在使用点提供标准化和一致的操作;平板、底部安装、顶部安装和壁式安装选项;以及紧凑的设计。世伟洛克专家可以向您展示鲜为人知的节约方案,例如在 SGP 和 SPU 之间的管路压力变化可以接受的情况下,如何使用单级 SGP 降低成本。

气体分配应用指南

查找有关我们的组件的详细信息。

气体分配系统的作用是按每种应用所需的压力和流量,将气体从高压源输送到设施中。大部分气体分配系统往往是围绕一个或一系列压力调节步骤而建立的,它可能拥有四个典型的子系统:气源进气口连接、初级气体压力控制、自动切换装置和使用点。本指南提供了世伟洛克气体分配系统的产品相关信息。

取样是在系统中收集流体或气体样本,其目的是将样品运送到实验室进行分析。请使用世伟洛克应用解决方案构建资料齐全的流体取样系统和控制系统并保证操作一致性。

世伟洛克为您精心准备的产品、服务和解决方案

案例分析:200 条气体管路。1 个综合解决方案。

一家大型英国化学品公司使用各种特殊气体来执行研究和开发功能。该公司利用世伟洛克气体分配计划增强了系统的安全性,并提升了效率

如何通过改善气体分配来减少您的维护支出

了解易用型气体面板和整体更高效的气体分配和输送系统如何帮助实验室、精炼厂和其他设施降低维护成本。

问答:如何通过高效的气体分配来降低成本并提高安全性

了解可能会妨碍重要气体分配系统的安全与效率的常见挑战以及对这些系统进行专业评估如何提供长期价值的信息。

提高气体分配系统的安全性和效率

气体分配系统对于帮助实验室、测试中心和工业设施以高效率运行至关重要。了解优化气体传输系统的健康,安全和降低成本,使你的团队走向成功。