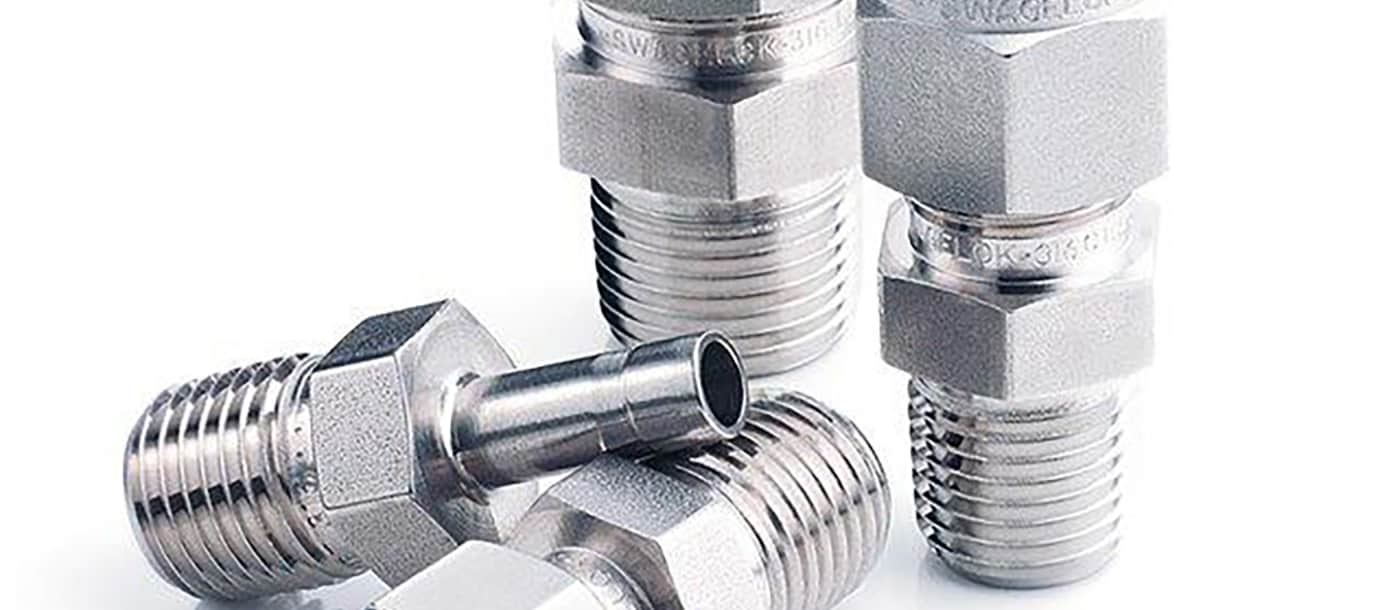

Фитинги высокой степени чистоты из перфторалкокси (PFA) с развальцовкой и мелкой резьбой

Фитинги Swagelok® из перфторалкокси (PFA) с развальцовкой и мелкой резьбой обеспечивают безопасную и эффективную работу газовых и жидкостных систем в условиях высокой степени чистоты. Они идеально подходят для использования в полупроводниковом производстве и агрессивных химических средах.

Получить рекомендации о выборе PFA фитингов с развальцовкойФитинги Swagelok® из перфторалкокси (PFA) с развальцовкой и мелкой резьбой выполнены из формованного фторполимера. Наши фитинги обладают такими характеристиками, как прочность на разрыв, устойчивость к проницаемости, термостабильность, и обеспечивают герметичность соединений в промышленных газовых и жидкостных системах. Фитинги Swagelok из перфторалкокси (PFA) совместимы с другими изделиями сверхвысокой чистоты, в том числе клапаны и трубки, а также обеспечивают полностью интегрированную систему для работы с агрессивными средами. Предусмотрены различные формы и размеры, а именно прямые, угловые и тройниковые конфигурации. В зависимости от нужд применения, предлагаются стандартные корпуса из PFA с гайками из поливинилиденфторида (PVDF), а также в конфигурациях all-PFA и all-PVDF.

Технические характеристики

| Номинальные параметры давления | До 275 psig (18,9 бар ман) |

| Номинальные параметры температуры | 75–350°F (23–176°C) |

| Корпус | Перфторалкокси (PFA) высокой степени чистоты |

| Гайки | поливинилиденфторид (PVDF) (стандартное исполнение), перфторалкокси (PFA) (опционально) |

| Торцевое соединение | Размеры: от 1/8 до 1 дюйма Конфигурации: Прямые отводы, колена, тройники, колпаки, заглушки, гайки, фитинги PVDF |

Каталоги фитингов высокой степени чистоты из перфторалкокси (PFA) с развальцовкой и мелкой резьбой

Получите подробные сведения о продукции, в том числе о материалах изготовления, номинальных параметрах давления и температуры, вариантах исполнения и вспомогательных принадлежностях.

Вводная информация о фитингах: Определение размера и шага резьбы

Даже у самых квалифицированных специалистов могут возникнуть трудности с определением резьбы. Менеджер по продукции Swagelok Энди Хичкок (Andy Hitchcock) объясняет, как определить размер и шаг резьбы на фитингах с помощью штангенциркуля, калибра шага и руководства по идентификации резьбы.

Читать о подборе фитинговРесурсы Swagelok специально для вас

Надежные решения в жидкостных и газовых системах для новых научно-исследовательских возможностей

Узнайте, почему финская компания-производитель криогенных рефрижераторов Bluefors доверяет компонентам и решениям Swagelok для жидкостных и газовых систем, которые способствуют развитию сферы квантовых вычислений, экспериментальной физики и других направлений.

Как создать более прибыльное производство полупроводников

Узнайте, почему выбор высококачественных деталей и узлов жидкостных и газовых систем может ускорить строительство завода по производству полупроводников и уменьшить общую стоимость владения в течение всего времени работы предприятия.

Improve Semiconductor Yield with Optimized Alloys

Discover how semiconductor fabricators can improve end-to-end production yields and improve long-term profitability by selecting the right metals for critical fluid system components.

Q&A: Semiconductor Manufacturing Past, Present, and Future

Find out how collaboration between semiconductor tool OEMs, microchip manufacturers, and fluid system solutions providers has enabled the semiconductor market to keep up with the demands of Moore’s Law for decades, and where we go from here.