世伟洛克® 卡套管接头和转换接头

双卡套卡套管接头具有防泄漏的密封性、出色的卡套管夹持力和抗振性,即使在重新装配后也能保持良好性能,可减少泄漏和停机时间。

卡套管接头 | 易于安装,有助于减轻安装人员的疲劳。

卡套管转换接头 | 实现各种连接并帮助消除难以对准的问题。

世伟洛克接头在降低各行业的泄漏风险和代价高昂的停机时间方面优于其他接头。先进的后卡套设计可隔离应力以抵抗振动、弯曲和变形,而获得专利的渗碳工艺可在不牺牲耐腐蚀性的情况下增强强度。世伟洛克卡套管接头易于安装和重新装配,与其他替代产品相比只需较少的工作量。

卡套管接头和转换接头有多种合金可供选择,以确保化学相容性,并提供专家主导的培训以确保正确安装。世伟洛克卡套管转换接头可与任何其他世伟洛克卡套管接头配合使用,无需储备特殊弯头和三通。与 316 不锈钢和 316 Ti 不锈钢合金卡套管配合使用的不锈钢世伟洛克卡套管接头已通过测试,符合 ECE R110 的要求,并且还具有 EC-79 认证。世伟洛克接头使用的材料符合 NACE MR0175/ISO 15156 和 MR0103 的冶金要求。此外,采用 2507 和 6MO 合金制成的接头符合 NORSOK M-630 和 M-650 标准。

卡套管接头和卡套管转换接头类别

卡套管接头和转换接头目录

世伟洛克卡套管接头和卡套管转换接头的尺寸从 1/16 到 2 in.,2 到 50 mm,并有一系列的配置,它们由各种材料制成,在包括化学加工和酸性气体在内的一系列应用中具有卓越的耐腐蚀性。在这里提供的产品资料中查找详细的产品信息,包括结构材料、额定压力和温度、工具和附件以及安装说明。

The proven Swagelok® tube fitting design manufactured from corrosion-resistant alloy 2507 with NORSOK M0630 and M-650 compliance standard, NACE MR0175/ISO 15156 optional.

仪表、直接安装和远程安装阀组及模块化系统 V、VB 和 VL 系列 2 阀、3 阀和 5 阀仪表阀组 VE 系列 2 阀、3 阀和 5 阀直接安装阀组 2 阀远程安装阀组 Mod 85 模块化仪表系统

浏览中高压接头

是否在寻找可承受超过 11 000 psi 压力的接头?了解我们的 FK 系列中压卡套管接头,其额定值适用于高达 22 500 psi (1551 bar) 的应用,而锥面螺纹接头的额定值适用于高达 60 000 psi (4134 bar) 的应用。

查找更高的压力额定值世伟洛克为您精心准备的产品、服务和解决方案

接头简介:识别螺纹尺寸和螺距

即使是有经验的专业人员也会遇到识别螺纹的困难。世伟洛克产品经理 Andy Hitchcock 解释如何使用游标卡尺、螺纹规和螺纹识别指南识别接头上的螺纹尺寸和螺距。

利用压缩卡套接头优化中压油气应用

对于石油天然气领域平台上资产中的中压应用,了解压缩式接头与传统的锥面及螺纹连接相比如何提高安装速度并带来性能优势。

沈鼓集团股份有限公司是如何提高系统安全性和可靠性的呢?

了解世伟洛克(上海)流体系统科技有限公司是如何帮助沈鼓集团股份有限公司在实现产品的一致性、可靠性和成本节省的同时,提高客户自身安全性和生产效率的。

卡套管转换接头如何能够消除对准问题

卡套管转换接头可以帮助消除棘手的对准位置,同时还可以减少库存。请观看本演示,了解如何使用世伟洛克® 卡套管转换接头在实现无泄漏密封的同时解决对准问题。

自 1947 年以来,世伟洛克在几乎所有行业的工业流体系统应用中,一直是推动卡套管接头技术发展的领导者。

世伟洛克创始人解说其革命性的卡套管接头

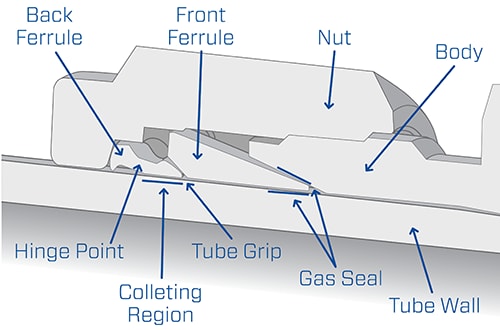

超过 75 年后的今天,世伟洛克卡套管接头凭借其独特的“铰链夹箍”作用,在提供持久、无泄漏的服务方面仍然值得信赖。抓紧式设计利用“铰链夹箍”作用在三个关键方面实现卓越性能:

卡套管抓紧

铰链夹箍作用提供更直接的卡套管接触/抓紧支撑。

气体密封

前卡套的磨光/抛光作用可在卡套管和本体斜面上形成接触集中区,从而实现更强的密封。

抗振性

夹箍区对卡套管抓紧处的应力集中区域进行了更好的隔离,可抵御弯折、变形和振动。

世伟洛克® 卡套管接头设计

所有 1/4 至 1 in. 和 6 至 25 mm 世伟洛克不锈钢卡套管接头均采用先进的几何形状、铰链夹箍抱紧作用的后卡套标准设计,以帮助安装人员建立更为一致的防泄漏卡套管连接。在这些尺寸下,一种获得专利的表面硬化工艺以及获得专利的凹槽和特定截面几何形状为世伟洛克后卡套提供了独一无二的工程学特点。具有铰链-夹箍作用的后卡套设计进一步提升了传统卡套设计所具有的强大性能。