Swagelok® Fittings

Swagelok fittings provide industrial fluid system operators with the reliability, ease of installation, and leak-tight performance needed to keep processes and equipment operating safely and efficiently.

View All FittingsSince the introduction of the Swagelok® tube fitting in 1947, industrial professionals have relied on Swagelok fittings to achieve leak-tight connections in their analytical, instrumentation, and small-bore process fluid systems. Whether you need fittings for corrosive environments, extreme temperatures, or high pressure, we offer reliable options to help you build connections you can trust. We offer a complete portfolio of fittings available in a variety of alloy materials for a wide range of industrial applications, including those with specialized requirements.

Swagelok fittings are held to high quality standards made possible by highly controlled processes, providing users peace of mind when integrating these versatile, high-performance fittings into their fluid system designs. Should you need technical support or training to make the best use of these products in your systems, help is available at nearly 200 authorized Swagelok sales and service locations across the globe.

Looking for fittings selection and installation advice?

Fittings Catalogs

Locate detailed product information, including materials of construction, pressure and temperature ratings, options, and accessories.

The proven Swagelok® tube fitting design manufactured from corrosion-resistant alloy 2507 with NORSOK M0630 and M-650 compliance standard, NACE MR0175/ISO 15156 optional.

可用于尺寸为 1/4、3/8、1/2、3/4 和 1 in. 的卡套管; PFA 和 PVDF 螺母选购件; 多种配置

仪表、直接安装和远程安装阀组及模块化系统 V、VB 和 VL 系列 2 阀、3 阀和 5 阀仪表阀组 VE 系列 2 阀、3 阀和 5 阀直接安装阀组 2 阀远程安装阀组 Mod 85 模块化仪表系统

FK and IPT Series Products Cone and thread or medium-pressure tube fitting connections Excellent corrosion resistance in chloride-containing environmentsManufactured to meet NORSOK and NACE® MR0175/ISO15156

1/8 至 1 in. 及 6 至 18 mm; 316、316L、316L VAR 和 316L VIM-VAR 不锈钢材料; 适用于手动或自动焊接设备的接头

不锈钢结构,碳氟化合物 FKM O 型圈; 可靠、可重复的密封性能; 提供 1/16 至 1 1/2 in. 尺寸的卡套管

Features: Metal components are machined from 316 stainless steel for use in rugged environments; Molded thermoplastic insulation with excellent electrical, chemical, and ultraviolet resistance and low water absorption maintains dielectric strength and integrity over a wide range of operating and climatic conditions; Gaugeable Swagelok® tube fitting or tapered pipe thread end connections (NPT/BSP) provide direct connection to tubing or piping system.

特点:从法兰管道系统到卡套管系统的无螺纹、无焊接过渡;法兰类型符合 ASME、DIN、EN 和 JIS 标准;一体式法兰锻件;可与长达 50 mm 和 2 in. 的世伟洛克® 卡套管接头端接配合使用

可用于尺寸为 1/16 至 2 in. 和 2 至 50 mm 的卡套管, 首次安装后具有一致的可检测性, 易于拆开和重新紧固, 有各种材料和结构

特点:316 不锈钢结构;温度高达 1000°F (537°C);中压 (MP) 接头,尺寸范围 —1/4 到 1 英寸,压力额定值 — 高达 20 000 psig (1378 bar);高压 (HP) 接头,尺寸范围 — 1/4 到 9/16 英寸,压力额定值 — 高达 60 000 psig (4134 bar);NACE® MR0175/ISO15156 合规性

温度从 20 至 204°C (70 至 400ºF); 工作压力可达 275 psig (18.9 bar); 尺寸为 1/8 in. 至 1/2 in.

40、50、63、100、115 和 160 mm (1 1/2、2、2 1/2、4、4 1/2 和 6 in.) 度盘尺寸; 精度符合 ASME、EN 和 JIS; 可供应多种端接,包括世伟洛克® (Swagelok®) 卡套管转换接头; 中心向后安装、下端向后安装和下端安装配置; 不锈钢和增强热塑结构

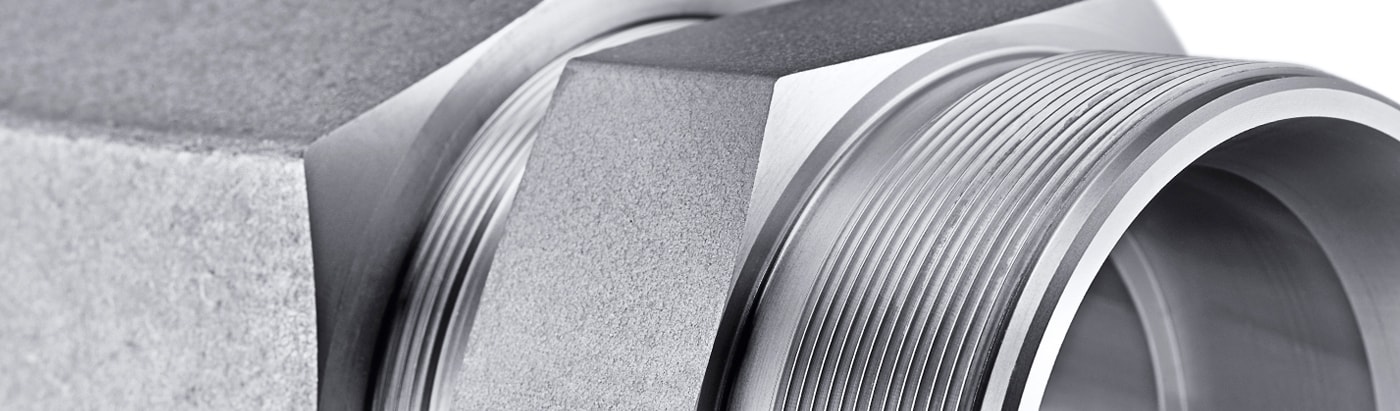

The Swagelok® Tube Fitting Advantage

Swagelok tube fittings are designed to meet your highest expectations for safety and dependability, featuring proven design, precise manufacturing, and superior raw materials.

Discover the AdvantageSwagelok Resources Curated for You

An Introduction to Fittings: Identifying Thread Size and Pitch

Even the most seasoned professionals can experience difficulty identifying threads. Swagelok product manager Andy Hitchcock explains how to identify thread size and pitch on your fittings using a caliper, pitch gauge and thread identification guide.

How Shenyang Blower Works Group Improved Safety and Reliability

Learn how Swagelok Shanghai has helped Shenyang Blower Works Group Corporation achieve consistency, reliability, and cost savings for its customers while improving its own safety and production efficiency.

Swagelok Tube Fitting Installation

This video demonstrates the integral steps for installing Swagelok tube fittings, which have earned a global reputation for consistency, quality, and reliability.

Swagelok Fittings

When the world’s most respected companies want to make lasting connections, they turn to Swagelok. We have established the standards for tube fitting performance in terms of leak-tight integrity, ease of installation, availability and support services. Our two-ferrule, stainless-steel tube fitting has earned a global reputation for consistency, quality, and reliability. This reputation is supported by our continuous product improvement efforts and by the fitting’s performance in thousands of diverse applications.