世伟洛克® 原子层沉积 (ALD) 阀

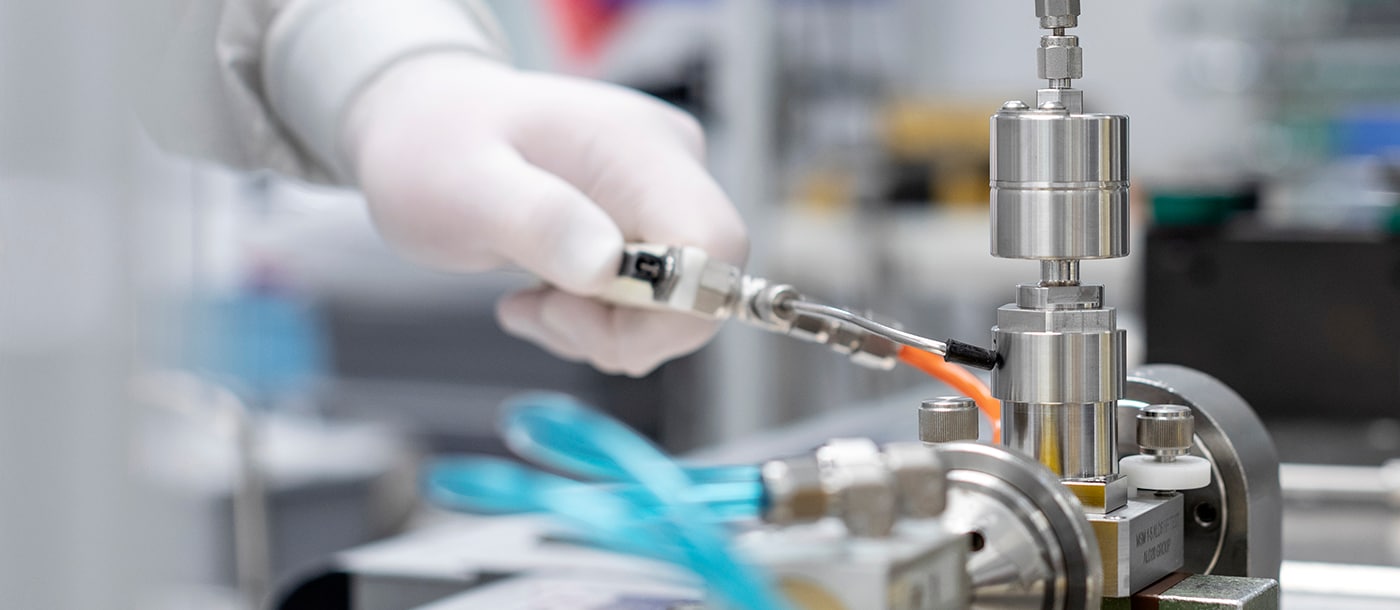

世伟洛克超高纯原子层沉积 (ALD) 阀具有超高循环寿命、高速执行、流量、热浸没和超高洁净度,可在先进半导体制造应用中实现精确进料并尽可能地提高芯片产量。

索取 ALD 阀门信息ALD 阀门问世以来,我们一直与半导体工具 OEM 和晶圆厂密切合作,提供的先进 ALD 阀门技术具有超高的精度、一致性、洁净度和高循环寿命,是紧跟市场快速创新步伐所必需的。世伟洛克® ALD 阀门可支持芯片生产效率的提高,并克服 ALD 工艺通常面临的挑战。

我们的 ALD 超高纯阀具有以下特点:

- 快速动作下的超高循环寿命

- Cv 范围从 0.27 至 1.7

- 指定型号的承温能力高达 392°F (200°C)

- 电子或光学执行机构位置传感选购件

- 洁净度适合超高纯应用

- 模块化表面安装、卡套管对焊和 VCR® 端接

Atomic Layer Deposition (ALD) Valves Categories

Ultrahigh-Purity Diaphragm Valves, ALD3 and ALD6 Series

ALD3 and ALD6 diaphragm valves offer ultrahigh cycle life, high-speed actuation, and strong performance in atomic layer deposition applications.

Ultrahigh-Purity Diaphragm Valves, ALD7 Series

The Swagelok® ALD7 ultrahigh-purity diaphragm valve offers the precision and consistency needed to maximize chip yields in semiconductor manufacturing applications.

Ultrahigh-Purity Valves for High-Flow Applications, ALD20 Series

Advance atomic layer deposition technology with flow rates 2–3x higher than other ALD valves with the ALD20 ultrahigh-purity valve.

原子层沉积 (ALD) 阀目录

查找详细的产品信息,包括结构材料、额定压力和温度、选购件及配件。

ALD 3, 6, and 7 Diaphragm Valves and ALD20 Bellows: Ultrahigh cycle life, high-speed actuation; Up to 392°F (200°C) w thermal actuators; Electronic actuator position-sensing; ultrahigh-purity applications; High flow capacity, PFA seat, Normally closed pneumatic actuation, Alloy 22 available

世伟洛克为您精心准备的产品、服务和解决方案

利用优化的合金提高半导体制造良率

了解半导体制造商如何通过为关键流体系统组件选择合适的金属材料,提高端到端制造良率并提高长期盈利能力。

问答:半导体制造的过去、现在与未来

了解半导体OEM设备商、微芯片制造商与流体系统解决方案提供商之间的协作如何使半导体市场在数十年来能够满足摩尔定律的要求以及未来的发展方向。

光纤设备制造商利用定制解决方案提高效率

自 20 世纪 80 年代以来,Rosendahl Nextrom 便与世伟洛克合作推动其业务的发展。了解有关使该公司超越其竞争对手并保持行业领先地位的解决方案的更多信息。

适合于科学前沿的可靠流体系统解决方案

了解为何芬兰稀释制冷机制造商 Bluefors 信赖世伟洛克提供的流体系统部件和解决方案,来助力于量子计算、实验物理学等领域。