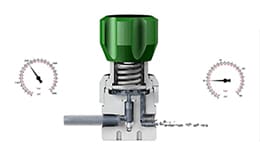

Détendeurs de gaz haut débit, haute pureté Swagelok® (série HF)

Faciles à régler, les régulateurs de la série HF offrent un contrôle précis de la pression et sont parfaitement adaptés aux débits élevés ainsi qu’aux process propres.

Se faire aider pour choisir des régulateurs de pressionLes régulateurs de la série HF sont conçus pour des systèmes aux débits élevés et permettent d’agencer de manière compacte les composants et les lignes de process d’un système. Les modèles à gaz sont nettement plus petits que les régulateurs à membrane traditionnels – une conception qui empêche un actionnement intempestif et simplifie l’installation du régulateur.

Ces régulateurs sont conçus pour des environnements qui exigent une propreté extrême. Assurant un contrôle durable et précis de la pression, les régulateurs série HF sont dotés d’un mécanisme de détection novateur qui limite l’effet de la pression d’alimentation et le phénomène de baisse graduelle de la pression de sortie. Pour cette raison, il arrive souvent que le système ne nécessite aucun réglage.

Les régulateurs sont dotés d’un clapet solidaire assurant un fonctionnement propre et une fermeture parfaite. Leur structure entièrement soudée ne nécessite pas de joints pour assurer l’étanchéité par rapport à l’atmosphère. Les clapets auto-centrés en PCTFE aident à prévenir le phénomène d’augmentation graduelle de la pression et assurent une parfaite étanchéité.

Les régulateurs série HF présentent également les caractéristiques suivantes :

- Pressions d’entrée maximales allant jusqu’à 206 bar (3000 psig)

- Pression de sortie réglable manuellement jusqu’à 10,3 bar (150 psig)

- Corps en acier inoxydable 316L VIM-VAR pour les applications très haute pureté

- Raccordements d’extrémité : raccord VCR® à demi-écrou 1/4 po ; tube à souder bout à bout 1/4 3/8 po ; montage modulaire en surface 1,5 po et 1,125 po

Catalogues des détendeurs de gaz haut débit, haute pureté série HF

Trouver des informations détaillées sur nos produits – matériaux de fabrication, pressions et températures nominales, options, accessoires, etc.

Features: Compact size with flow rates up to 200 std L/min; Maximum inlet pressures up to 500 psig (34.4 bar); Manually adjustable outlet pressure up to 150 psig (10.3 bar); 316L VIM-VAR stainless steel body for ultrahigh-purity applications; 1/4 in. VCR® metal face seal; 1/4 in. tube butt weld; 1.5 in. and 1.125 in. C-seal and W-seal modular surface-mount end connections

Swagelok® HF series are high-flow, high-purity pressure regulators available in compact preset or dome-loaded models with flow rates up to 300 std L/min.

Besoin d’aide pour choisir le bon régulateur de pression ?

Découvrez plusieurs types de régulateurs utilisés dans différentes conditions avec notre vidéo expliquant comment choisir un régulateur.

Trouver le bon régulateurLes ressources de Swagelok sélectionnées pour vous

Contrôler l’effet de la pression d’alimentation (SPE) dans un détendeur

L’effet de la pression d’alimentation, également appelé dépendance, est une relation inverse entre les variables de pression d’entrée et de pression de sortie dans un détendeur. Découvrez comment contrôler ce phénomène dans vos détendeurs grâce aux conseils de Swagelok.

Des tests rigoureux pour garantir la fiabilité des régulateurs

Vous êtes-vous déjà demandé à quels tests était soumis un produit conçu pour fonctionner dans des conditions extrêmes ? Passez les portes des laboratoires pour suivre le développement de régulateurs de la série RHPS conçus pour fonctionner à des températures bien inférieures à zéro.

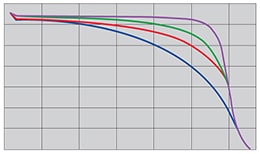

Rapprocher la courbe de débit d’un détendeur de l’horizontale pour atténuer la baisse graduelle de la pression de sortie (droop)

Tout détendeur est confronté au phénomène de baisse graduelle de la pression de sortie (droop). Découvrez comment limiter ce phénomène et rapprocher les courbes de débit de l’horizontale avec différentes configurations de détendeurs à dôme.

Comment utiliser un détendeur pour réduire le temps de réponse d’un système d’instrumentation analytique

Le temps de réponse d’un système d’analyse est souvent sous-estimé ou mal compris. L’utilisation d’un détendeur permet de réduire ce temps de réponse. Découvrez comment maîtriser le temps de réponse de votre système d’analyse grâce à ces conseils.