Gasverteilungssysteme von Swagelok®

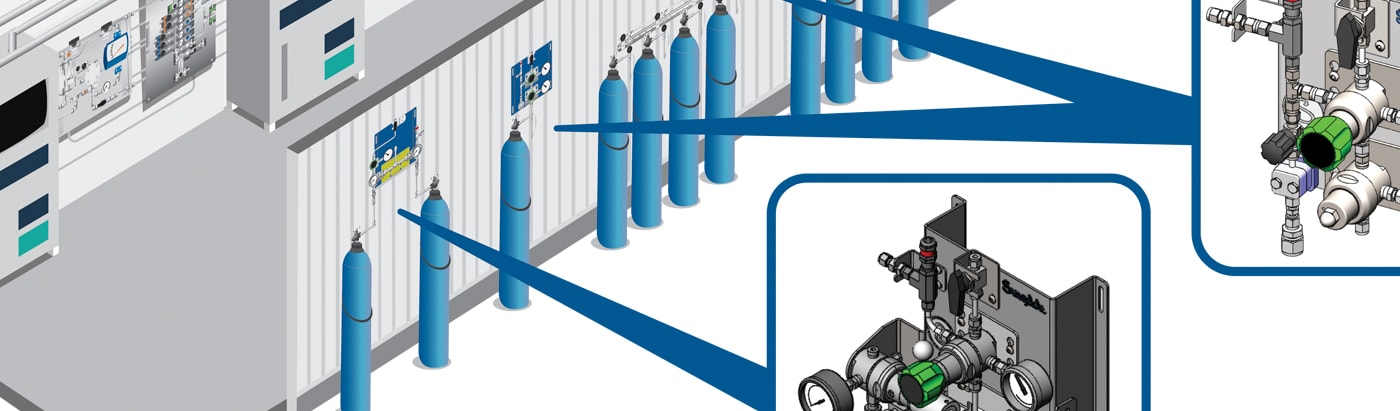

Für viele Anlagenbetreiber in Industrie, Produktion und Forschung übernehmen Gasverteilungssysteme kritische Funktionen. Denn die sichere, zuverlässige und effektive Einspeisung von Gasen bildet die Grundlage für einen erfolgreichen Anlagenbetrieb. Die Funktion von Gasverteilungssystemen besteht darin, den entsprechenden Betriebsbereich mit druckbeaufschlagten Gasen gemäß den für die jeweilige Anwendung erforderlichen Druck- und Durchflussraten zu versorgen.

Einen Experten kontaktierenDie standardisierten Gasverteilungssysteme von Swagelok werden vollständig montiert und geprüft geliefert. Als einzelne Teilenummern über den Anwendungsleitfaden erhältlich, erleichtern sie Ingenieuren Spezifikations- und Beschaffungsvorgänge für neue Systeme.

Die modularen Gasverteilungssysteme von Swagelok zeichnen sich zugunsten von weniger potenziellen Leckagestellen durch ein Minimum an Gewindeverbindungen aus. Die intuitive Kennzeichnung trägt dazu bei, dass sie sicher und einfach in der Anwendung und Wartung sind. Darüber hinaus sind sie durch die eingeschränkte Nutzungsdauergarantie von Swagelok abgedeckt.

Erfahren Sie mehr über die Gasverteilungssysteme von Swagelok®

Gasverteilungssysteme, die in den meisten Fällen basierend auf einem oder mehreren Druckregulierungs-Abschnitten gebaut sind, können die folgenden vier typischen Untersysteme umfassen:

- Swagelok® Source Inlet (SSI)

- Swagelok® Gas Panel (SGP)

- Swagelok® Changeover (SCO)

- Swagelok® Point-of-Use (SPU)

Swagelok® Source Inlet (SSI)

Der Quelleingang verbindet eine druckbeaufschlagte Gasquelle mit dem Rest des Gasverteilungssystems. Es ist wichtig, dass der Eingang mit den entsprechenden Zylinderanschlüssen, Schläuchen, Leitungen, Filtern, sowie Entlüftungs-, Spül- und Druckentlastungsfunktionen ausgestattet ist, damit das Gas sicher in die primäre Gasdrucksteuerung oder das automatische Umschaltsystem gespeist wird. Bei Verwendung einer einzigen Gasflasche kann die Baugruppe einfach nur aus einem Schlauch mit einem Zylinderanschluss bestehen. Wenn allerdings mehrere Flaschen notwendig sind, ist unter Umständen ein Ventilblock mit mehreren Schläuchen und Ventilen erforderlich. Swagelok bietet vielfältige Konfigurationsmöglichkeiten für individuelle Spül- und Entlüftungsanforderungen beim Austausch der Gasflaschen. Die Sicherheit des Bedienpersonals ist bei allen Lösungen stets gewährleistet und es besteht die Option, einzelne Leitungen zu entlüften, um Stillstandszeiten zu minimieren.

Die technischen Experten von Swagelok stellen sicher, dass alle Komponenten eingebaut und ordnungsgemäß spezifiziert sind, nur so viele Verbindungsstellen wie nötig vorgehalten werden, Schläuche nicht herunterfallen können und alle Komponenten richtig abgesichert sind. Darüber hinaus bieten sie kompetente Beratung zu den Anforderungen an die technische Ausrüstung (z. B. entsprechende Schläuche für spezielle Gase).

Swagelok® Gas Panel (SGP)

Die primäre Gasdruckregelung, das Swagelok Gas Panel (SGP), sorgt für die erste Druckminderung und stellt sicher, dass das Gas mit der korrekten Durchflussrate in die nächste Stufe des Systems gelangt. Die Druckminderung erfolgt entweder einstufig mithilfe eines einzelnen Druckreglers oder zweistufig durch eine Kombination aus zwei Druckreglern.

Swagelok bietet modulare Panels, die sich durch eine einfache Wartung auszeichnen, da sich jedes Teil mühelos über eine Swagelok-Verschraubung entfernen lässt. Eine Entfernung des Panels ist daher nie erforderlich. Des Weiteren stehen bei Bedarf verschiedene Optionen zur farblichen Kennzeichnung von Reglern und Ventilen zur Verfügung. Gerne berät Sie Swagelok und erklärt Ihnen, wann eine zweistufige Druckminderung erforderlich ist.

Video zur Funktion des SGP ansehen

Swagelok® Changeover (SCO)

Die automatische Umschaltung wechselt nahtlos von einer Gasquelle zur nächsten und stellt so eine kontinuierliche Versorgung sicher. Die Regelung erfolgt über die abgestuften Einstellwerte zweier Druckregler, sodass das System auch beim Wechsel der primären Gasquelle weiterbetrieben werden kann. Die Umschaltstation erlaubt die Spezifizierung bestimmter Umschaltpunkte, um weniger Gasverlust in den Flaschen sicherzustellen.

Die Lösungen von Swagelok sorgen dafür, dass der Umschaltpunkt konstant bleibt und bieten darüber hinaus eine optionale Leitungssteuerung, sollte Ihr System einen nachgeschalteten Point-of-Use-Regler enthalten. So können die zusätzlichen Kosten für einen Regler am SCO entfallen. Die Experten von Swagelok geben Ihren Teams gerne praktische Tipps zu Themen wie Systemfunktionalität, Fehlerbehebung und Aufrechterhaltung des Betriebs.

Video zur Funktion des SCO ansehen

Swagelok® Point-of-Use (SPU)

Der Swagelok Point-of-Use (SPU) stellt die kritische letzte Stufe der Regelung dar, bevor das Gas zum Einsatz kommt. Diese Systeme bestehen normalerweise aus einem Druckregler, einem Manometer und einem Absperrventil und liefern den Bedienern und Technikern eine praktische und genaue Methode zur Druckeinstellung, um auf die Anforderungen im Prüfstand oder der Geräte einzugehen.

Die Point-of-Use-Lösungen von Swagelok sorgen für einen standardisierten und gleichmäßigen Betrieb, zeichnen sich durch ein flaches und kompaktes Design aus und sind mit mehreren Halterungsoptionen verfügbar, um eine Montage an verschiedenen Stellen zu ermöglichen. Die Experten von Swagelok können Ihnen außerdem Einsparpotenziale aufzeigen, z. B. wie ein einstufiger SGP zur Kostenminimierung verwendet werden kann oder wann ein variierender Leitungsdruck zwischen SGP und SPU toleriert werden kann.

Anwendungsleitfäden zum Thema Gasverteilung

Detaillierte Informationen zu unseren Baugruppen anfordern

Gas distribution systems work to deliver gases from a high-pressure source to the facility at the pressure and flow rate required by each application. Most often built around one or a series of pressure regulation steps, gas distribution systems can have four typical subsystems: Source Inlet Connection, Primary Gas Pressure Control, Automatic Changeover, and Point-of-Use. This guide provides information on Swagelok's gas distribution system offerings.

Grab sampling is the collecting of a sample of fluid or gas in a system with the intent of transporting the sample to a laboratory for analysis. Use Swagelok application solutions to create fully documented fluid sampling and control systems and bring consistency to your operations.

Wie funktionieren industrielle Gasverteilungssysteme

Erfahren Sie mehr über die Faktoren, die direkte Auswirkungen auf die Auslegung, den Betrieb und die Instandhaltung von industriellen Gasverteilungssystemen haben, um Ihren Anlagenbetrieb noch effizienter zu gestalten.

Whitepaper lesenRessourcenzentrum

Sicherheit und Risikoreduktion in Gasverteilungssystemen

Erfahren Sie, wie Sie Risiken bei der Auslegung, Installation und Wartung von Gasverteilungssystemen erkennen und wie Sie mit den passenden Komponenten einen sicheren und zuverlässigen Betrieb gewährleisten.

Wie Sie mithilfe eines optimierten Gasverteilungssystems Ihre Wartungskosten reduzieren

Erfahren Sie, wie einfach zu bedienende Gasverteiler und optimierte Gasverteilungssysteme dazu beitragen, Wartungskosten in Laboren, Raffinerien und anderen Einrichtungen zu reduzieren.

Q&A: Wie Sie mit einer effizienteren Gasverteilung Kosten reduzieren und die Sicherheit erhöhen können

Erfahren Sie, was sich häufig negativ auf die Sicherheit und Effizienz Ihrer Gasverteilungssysteme auswirkt, und wie eine professionelle Überprüfung dieser Systeme sich langfristig lohnt.

Höhere Sicherheit und Effizienz in Gasverteilungssystemen

Gasverteilungssysteme sind in Laboren, Testzentren und industriellen Produktionseinrichtungen von entscheidender Bedeutung, um einen Betrieb bei maximaler Effizienz zu gewährleisten. Erfahren Sie mehr darüber, wie Sie Ihre Gasverteilungssysteme sicherer und zuverlässiger machen, Kosten senken und so die Weichen auf Erfolg stellen.