世伟洛克® PTFE 和 PFA 内管软管

世伟洛克 PTFE 和 PFA 内芯软管具有使用寿命长、柔韧性高、耐化学腐蚀性强、抗渗透性强和易于清洁等特点,是在各种一般和特殊应用中控制成本的理想选择。

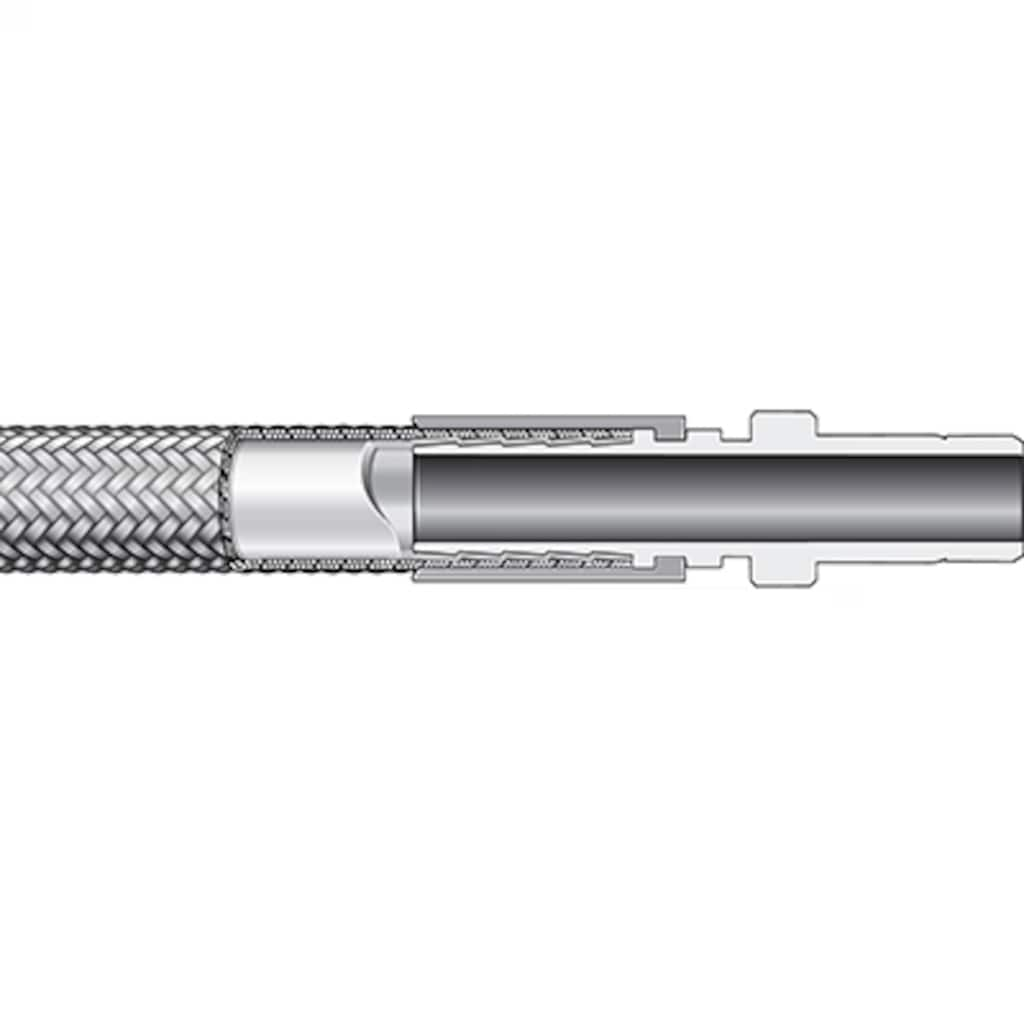

查看 PTFE 和 PFA 内管软管世伟洛克 PTFE 和 PFA 软管提供光滑内孔、波纹和混合型选购件,以满足不同的清洁度、柔韧性和抗渗透性需求。所有世伟洛克 PTFE 和 PFA 软管均经过压力测试,以确保符合我们严格的质量标准。部分软管可使用碳黑填充内管材料,以实现静电消散。

PTFE 软管可进行热处理或“烧结”,以提高抗渗透性,降低成本和与气体泄漏有关的安全风险。我们提供慢烧结或后烧结选择,其限制气体泄漏的性能大大优于非烧结软管,而且我们的后烧结软管的抗气体渗透性在业内名列前茅。

世伟洛克 PFA 软管的光滑内孔内管和柔韧性使其成为卫生应用的理想选择。光滑的内壁可减少流动限制并提高排水性,从而实现精确度和清洁度。硅胶外层容易清洗,防止细菌堆积,保护不锈钢编织层,防止烧灼,并有助于保持工艺温度。

是否需要帮助选择合适的软管?

PTFE and PFA Hose Categories

PFA Core Hose Smooth Bore

Learn more about our PFA core hose, whose smooth-bore core and easy-to-clean surface makes it ideal for sanitary applications requiring FDA compliance.

PTFE Core Hose Convoluted

Explore convoluted PTFE (fluoropolymer) core hose options for applications where low weight, flexibility, and chemical compatibility are necessary.

PTFE Core Hose Smooth Bore with 316L SS Convoluted Cover

Use PTFE smooth bore core hose with a 316L stainless steel convoluted cover where ultra-high purity is critical and permeation to the atmosphere is undesirable.

PTFE Core Hose Smooth Bore, B-Series

The B series PTFE hose with 304 SS braid ensures chemical compatibility and pressure containment. Working pressures: vacuum to 3000 psig. Custom options available.

PTFE Core Hose Smooth Bore, F-Series

The F series nonmetallic PTFE hose with fiber stainless steel braid resists kinking and offers flexibility, chemical compatibility, and various end connections.

PTFE Core Hose Smooth Bore, S-Series

Discover the S series silicone-covered PTFE smooth bore hose with 304 SS braid, offering flexibility, chemical compatibility, and a range of sizes and end connections.

PTFE Core Hose Smooth Bore, T-Series

Browse hose options that have a smooth-bore PTFE (fluoropolymer) core and a protective 304 stainless steel braid layer.

PTFE Core Hose Smooth Bore, X-Series

The X series PTFE hose with 304 SS braid offers flexibility and chemical compatibility. Sizes: 1/4 to 1 inch, pressures: vacuum to 3500 psig. Custom options available.

软管和柔性卡套管样本

查找详细的产品信息,包括结构材料、额定压力和温度、选购件及配件。

Swagelok® hose and tubing products are available in custom lengths, in diameters 2 inches and under, and with many types of end connections, core materials, and reinforcement styles to suit a broad spectrum of pressures and temperatures.

世伟洛克为您精心准备的产品、服务和解决方案

提高软管安全性并降低工厂成本的三个步骤

在工厂定期维护期间,人们通常不太重视工业软管的安全性。软管的泄漏和磨损会导致您的设备处于风险中,应该得到重视。了解避免危险状况同时降低工厂成本的建议。

工业软管维护计划如何为您的工厂节省大笔费用

了解更换工业软管的适当时机可以为您工厂节省大量维护成本。了解如何评估您的系统并制定预防性维护计划以管理软管的生命周期。

工业软管更换:内管材料注意事项

在选择工业软管时,首先要考虑内管,即软管最内层。通过世伟洛克专家提供的内管材料和管壁构造信息,了解如何为您的应用选择理想的软管。

如何选择正确的软管加强

工业软管通常包含有助于延长使用寿命和提高性能的关键加强层。了解不同的加强层类型,以及适合不同流体系统应用的加强层类型。

波纹和光滑 PTFE 内层软管

波纹和光滑 PTFE 内层软管具有化学相容性、排水性,并且可实现精确的流量控制。提供适合特殊应用的静电消散、炭黑填充内管、符合 FDA 标准或通过 ECE R110 替代燃料认证的软管。选购件包括定制的软管长度、软管外层和多种端接。